Chapter 23

PROPOSED 20 MW PEAT FIRED POWER PLANT OF HOSAF GROUP AT MADARIPUR

Presented By:

Engr. A. K. M. Shamsuddin;

Project Director;

Khalashpir Coal Mine TEFS Project;

HOSAF GROUP OF COMPANIES;

Dhaka, December 01, 2013.

Chapter-23: Formation & Uses of Peat

- Peat forms when plant material, usually in marshy areas, is inhibited from decaying fully by acidic anaerobic conditions. It is composed of mainly of marshlands vegetation; trees, grasses, fungi, as well as other types of organic remains, such as insects and animal remains.

- Peat is the initial stage in the formation of coal and is formed by the disintegration and decomposition of vegetable matter that either accumulated where it grew or was transported from surrounding areas.

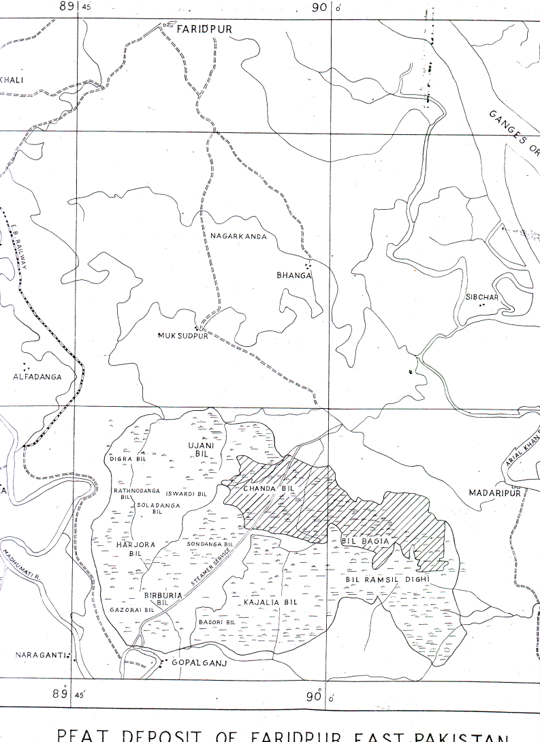

- Bangladesh Peat Deposits occur in the marshy areas of the north-eastern, central and south western parts with a total reserve of 170 million tons. Calorific value of peat ranges from 6000 to 7000 BTU/lb (3334 to 3889 Kcal/Kg).

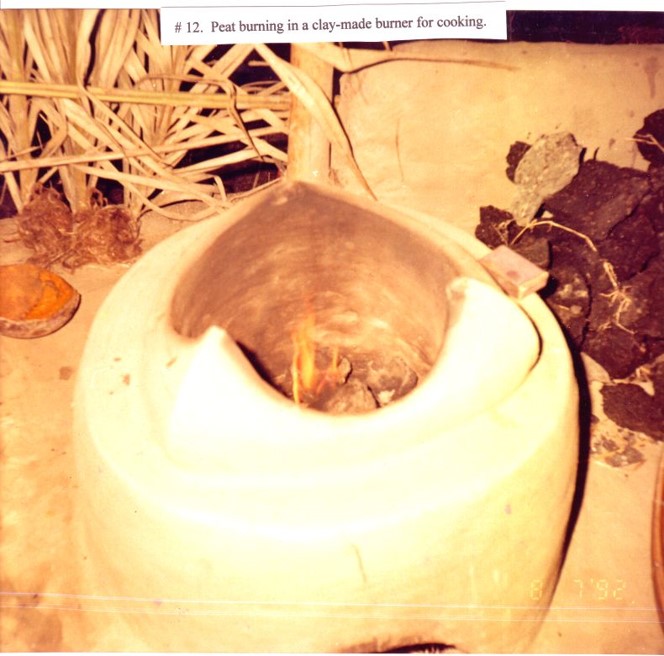

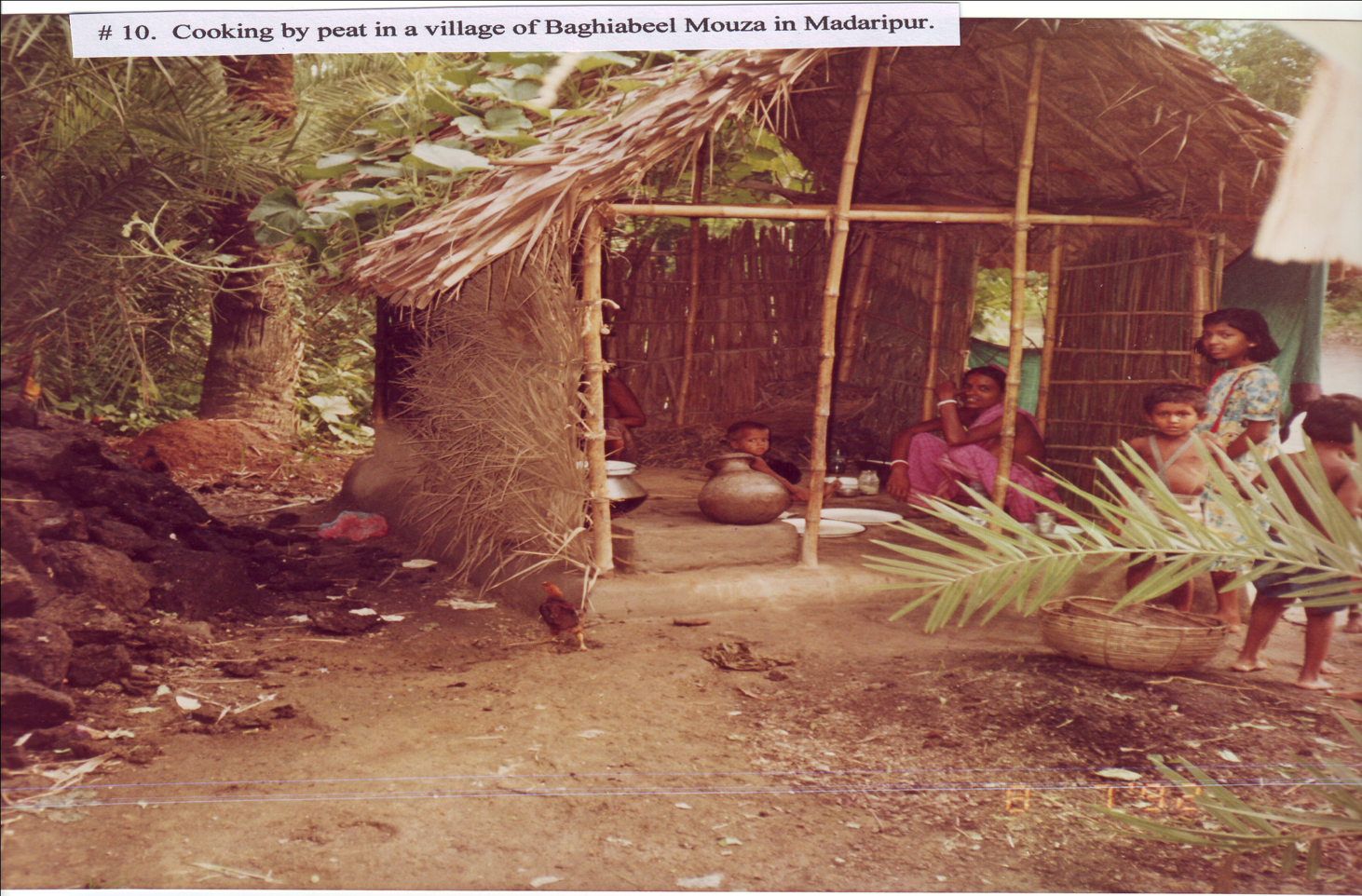

- Peat can be used as fuel for domestic purposes, brick manufacturing, boilers, small scale power plants (10 MW, 20 MW, and 25 MW), etc.

Bangladesh Peat Deposit

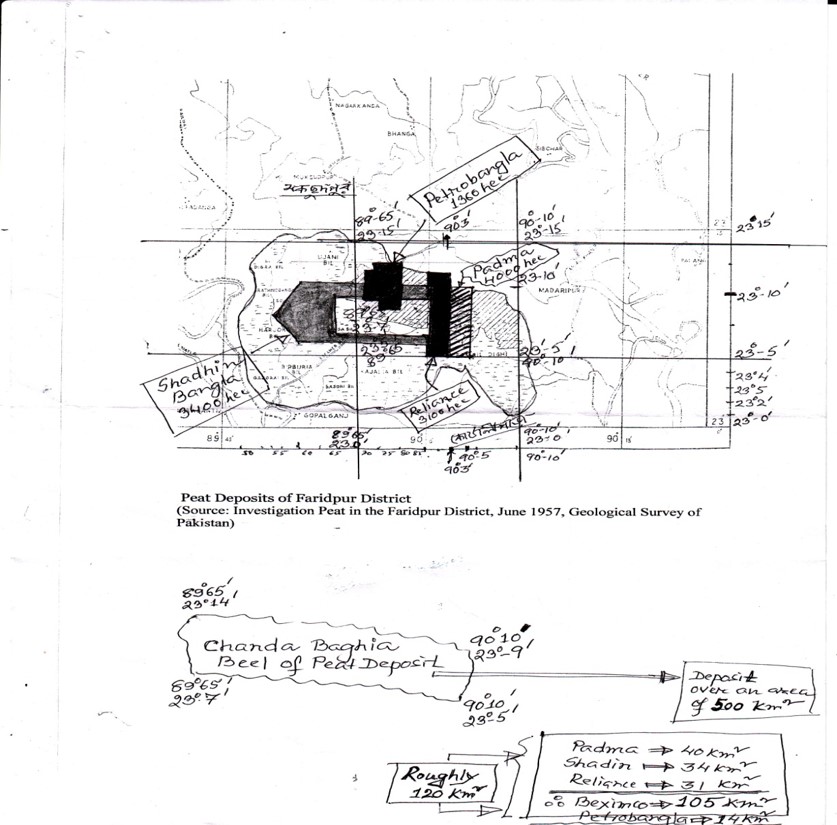

- The then Geological Survey of Pakistan (GSP) discovered peat in greater Khulna & Faridpur districts during routine exploration work in 1957 covering an area of 500 sq. km.

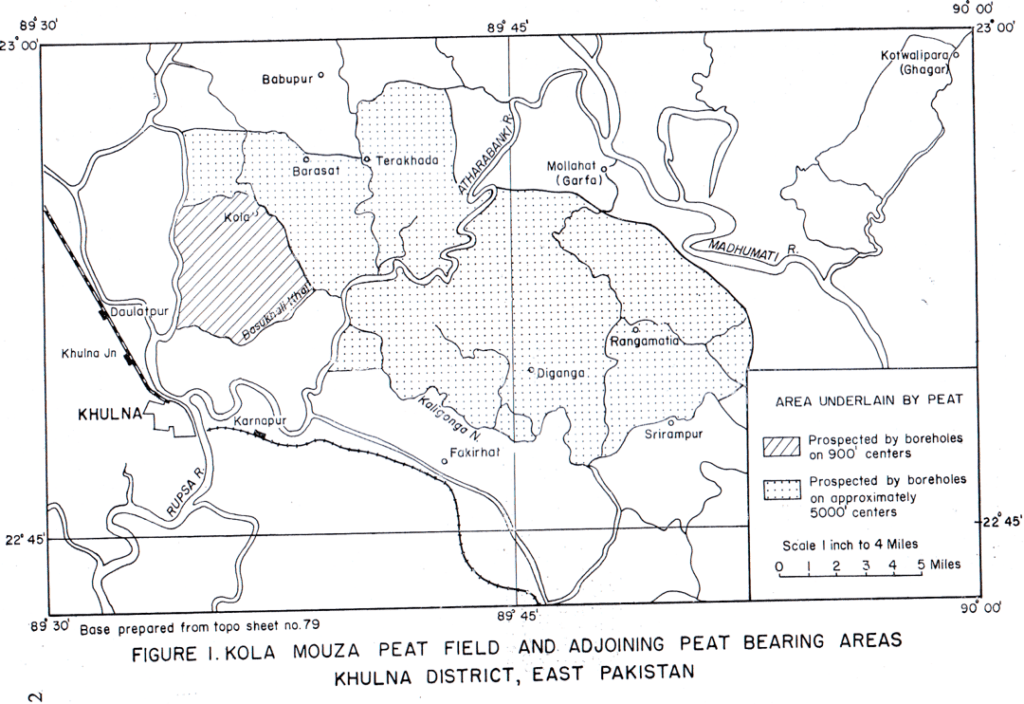

- In 1979-80, the then Bangladesh Mineral Exploration & Development Corporation (BMEDC) in collaboration with Geological Survey of Bangladesh (GSB) carried out a Feasibility Study on peat deposits in Kola Mouza, Khulna. The study advocated using peat for domestic and brick-burning purposes.

- In 1983-84, a survey & investigation sponsored by UNDP reveals that a reserve of 400 million tons of peat exist in various parts of Bangladesh.

- In 1986, Petrobangla conducted a detail study on peat with CIDA assistance in Madaripur, Khulna and Gopalganj region. The study located 61.26 million tons of peat covering areas of 205 sq. km.

- Average thickness of peat is 6.0 ft and it is at a depth of average 5 ft. from the surface. Reserves & Test Results of Faridpur and Khulna Peat Deposits have been shown in below table.

|

Peat Deposits |

Depth in meter |

Thickness in meter |

Area in sq.km. |

Reserve (Mt) |

Carbon (%) |

Ash (%) |

Moisture (%) |

Volatile Matter (%) |

|

Baghia Chanda Bill, Madaripur |

0.4 |

0.6-3.3 |

500 |

150 |

24 |

16.65 |

17.1 |

42.30 |

|

Kolamouza, Khulna |

0.04-2.5 |

0.2-4 |

25 |

8 |

29.2 |

24.80 |

13.70 |

42.30 |

RECOMMENDATIONS OF CIDA STUDY

- Peat at 35% moisture suitable for power generation and manufacturing of briquette.

- Installation of 10.MW Pilot Power Plant using Khulna peat.

- Installation of two 25-MW commercial units using Madaripur peat.

- Cost of peat fuel is Tk. 0.81 per kilowatt hour (1986-basis) as compared to Tk. 1.51 for furnace oil when used for power generation.

- Briquette of peat for use in industry & domestic purposes.

PETROBANGLA PEAT MINING PROJECT 1992-94

- Name of Project: “Peat Development & Demonstration Project”.

- Project Director: Engr AKM Shamsuddin, General Manager, Mineral Exploration Division, Petrobangla.

- Date of Commencement & Completion: With the approval of Govt. of Bangladesh, Petrobangla undertook a project in Madaripur district in the style of: “Peat Development & Demonstration Project” which commenced in the month of April 1992 and ended in 1995.

Objectives of Petrobangla Project

- To run a demonstration scheme for 3-years with production of 300, 4000 & 2,200 tons of peat/briquettes in the 1st, 2nd & 3rd year respectively.

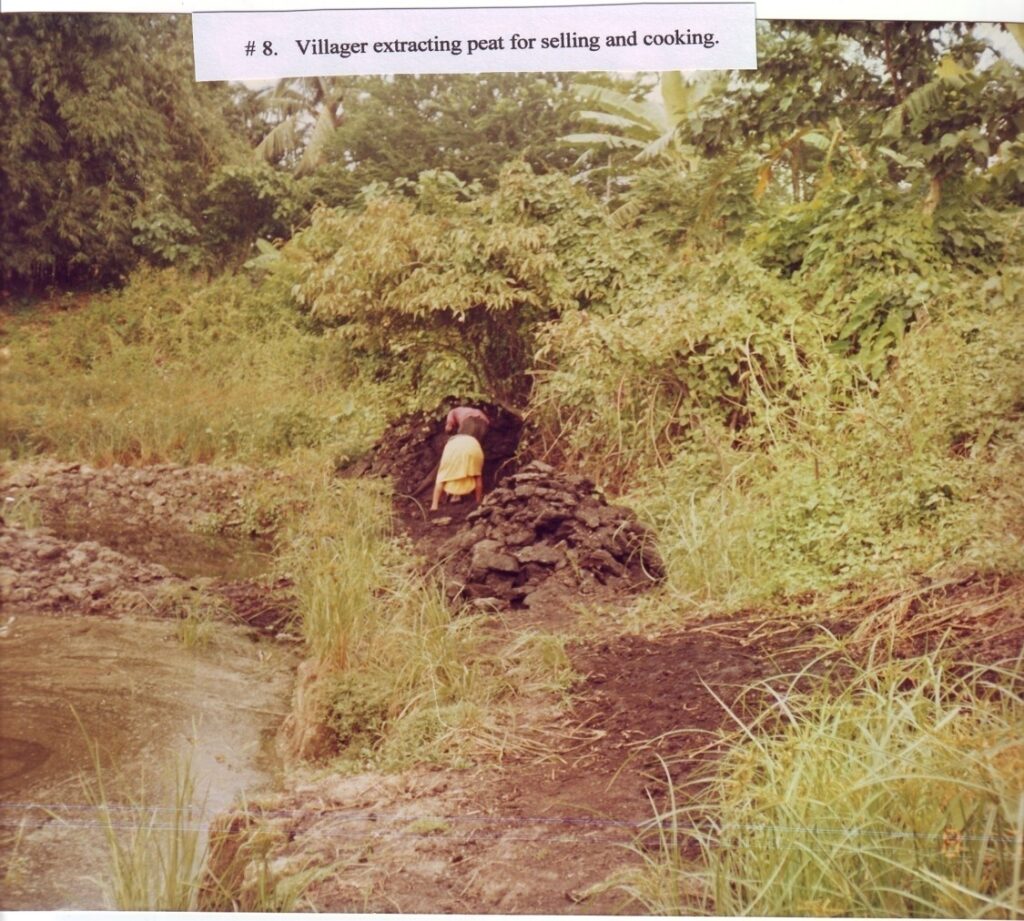

- To introduce peat as a fuel for domestic and brick burning purposes.

- To establish the market of peat as fuel to the local areas.

- To observe the effect of project on environment.

- To determine the possibility of making briquettes for energy fuel.

- To provide employment opportunities for the local unemployed low income group people.

- To determine viability of peat mines on financial as well as socio-economic point of view.

Petrobangla Project Description

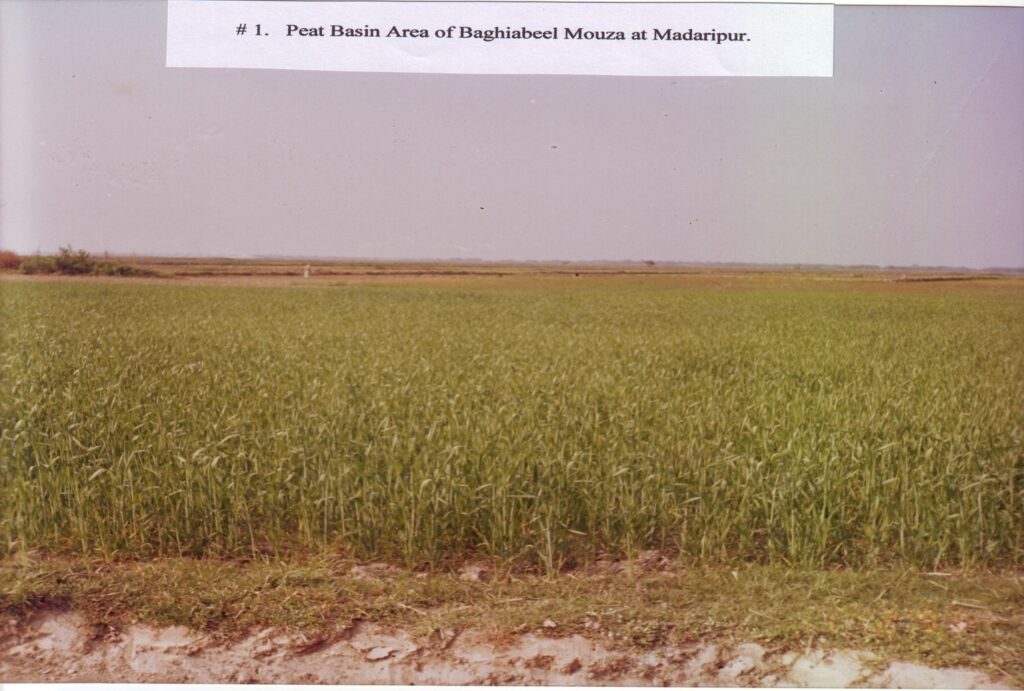

- A site covering an area of 15.00 acres at Barabahadarpur Mouza of Kendua Union under Madaripur Sadar Thana was selected where peat thickness varies from 1.7m. to 4.25m. and thickness of overburden varies from 0.25m to 1.35m for extraction of peat.

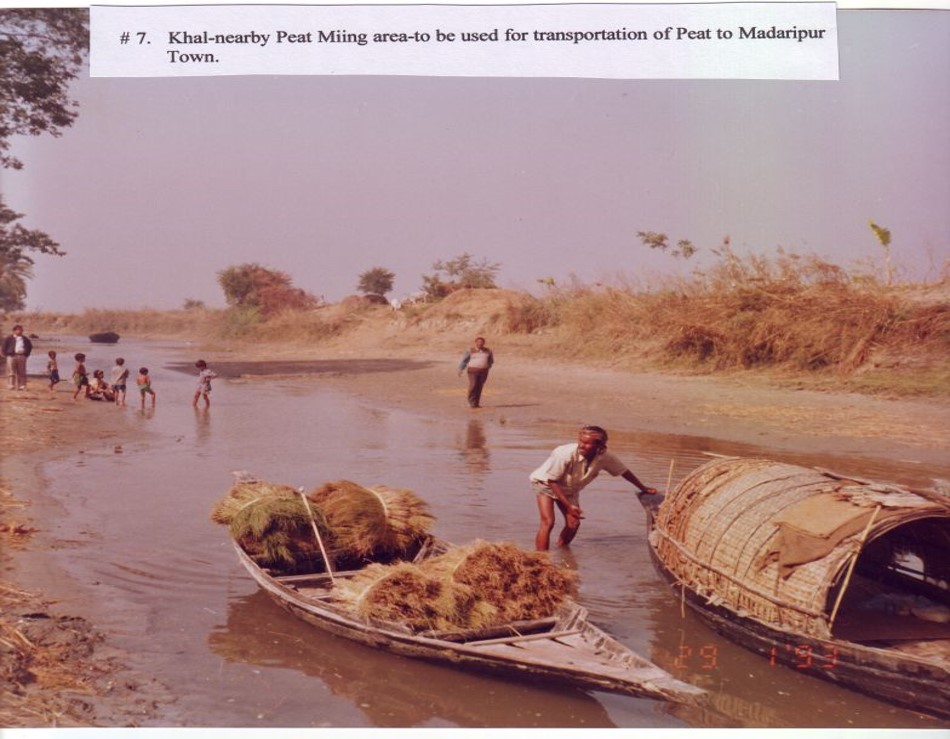

- The site was about 15 km south-west of Madaripur town & was connected to Madaripur to Mostafapur and 7-km waterway from Mostafapur to mine-site.

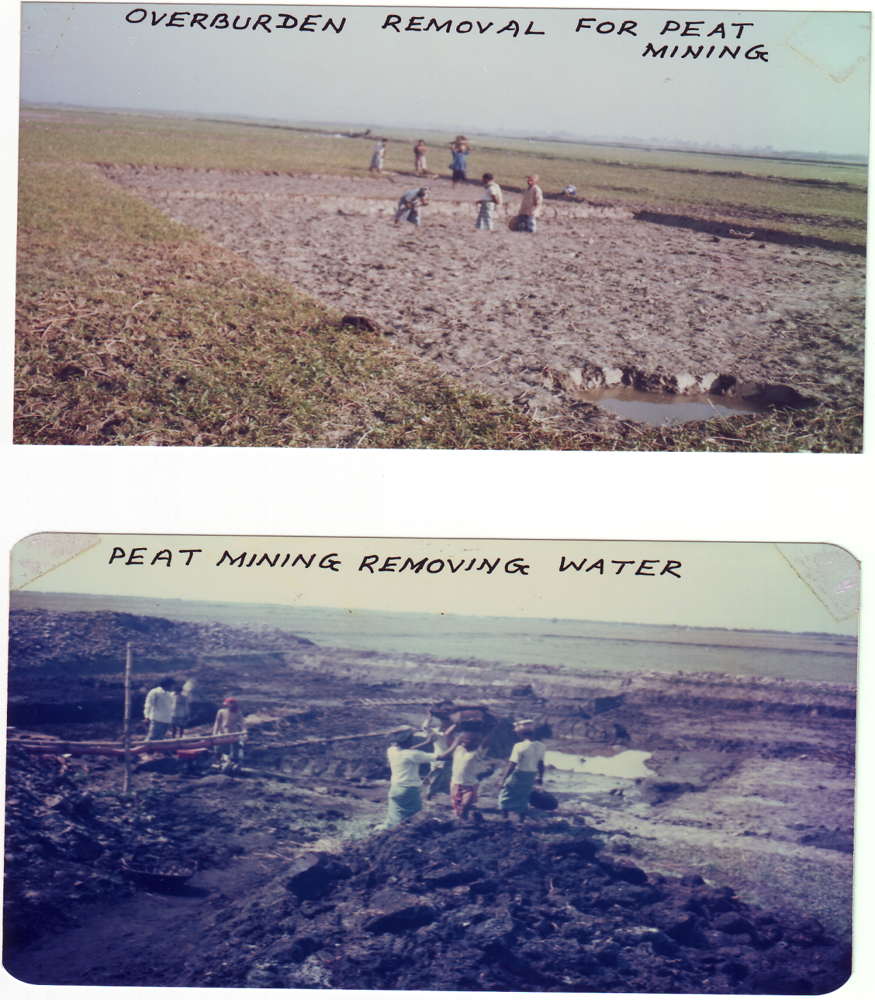

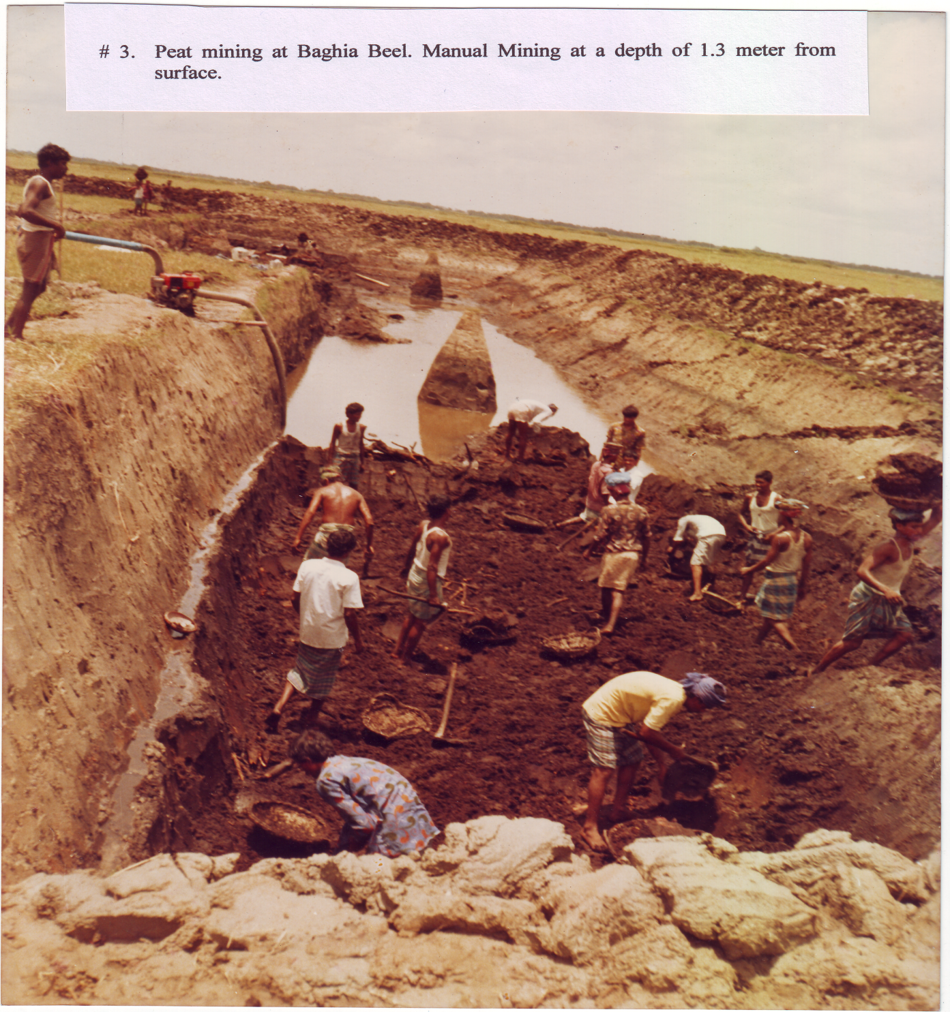

- Removal of overburden and extraction of peat was carried out manually using local labour and local equipment like kodal, konti, belcha, kural, etc.

- Overburden & peat were stacked separately by the mine site.

- Peat drying was also carried out at the site.

- Till June 1994, about 1800 tons of wet peat had been extracted.

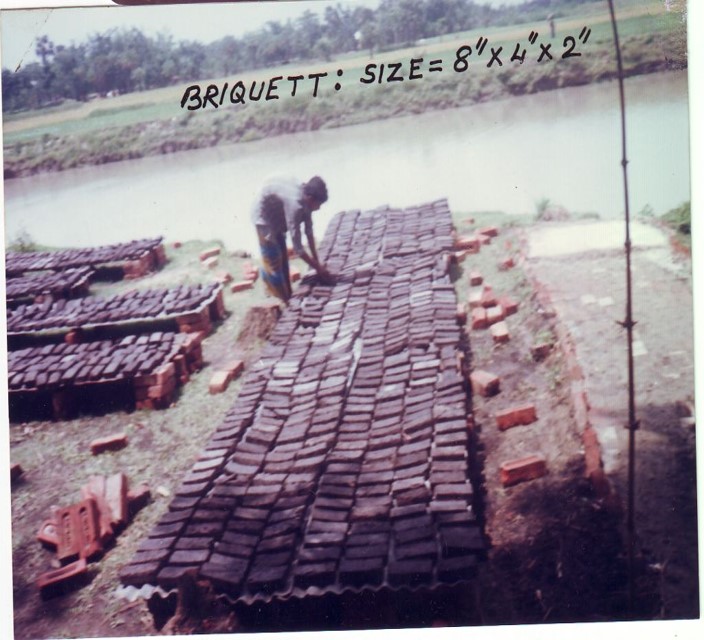

- A briquetting machine, production capacity being 100 briquetts of size 8″X4″X2″ each per hour, was installed at Gathmajee area near Mostafapur which was well connected with Madaripur town by road & river.

- The machine was made locally and for the first time in Bangladesh such machine was made for peat briquetting.

- Till November 1995 – 55,500 pieces of briquetts were produced. Weight of briquetts was about 55.5 tons in wet condition. On drying (moisture free) it was about 18.5 tons.

Findings of Petrobangla Peat Project

- About 46 tons of peat were distributed among brickfields, sweet shops, houses in Madaripur town to demonstrate use of peat.

- Results were encouraging. It was established that peat can be used in brick-fields & other commercial & domestic sectors profitably.

- Petrobangla Project people made an effort to convince people to use peat. People were convinced.

- Costs of production of peat/briquetts were roughly Tk. 2000/- tons which was very high.

- A small quantity of peat was sold at Taka 750/- per ton at subsidies rate to promote sale.

- Project Director opined that efforts were required to be taken to produce peat/briquette at Taka 600 to 700 per ton. If briquette and sales of peat could be done from the mine site, overall production cost can be substantially reduced.

- Since it was a Govt. funded project under Annual Development Plan (ADP) for 2-years, the project was closed after expending ADP fund as per allocation, successfully, with the recommendations to use peat for domestic, commercial and brick-fields.

PwC Recommends Peat for Power Generation

PricewaterhouseCoopers Pvt. Limited, A reputed Mining Consulting Company of India in their recent study (September 2013) on “Bangladesh Coal” have recommended to consider using peat as an additional source of fuel, after gas and coal, for generation of electricity in Bangladesh because of its reasonable peat reserves at very shallow depths and easy accessibility by road, rail and river to peat deposits.

Peat Mining Worldwide

Peat is harvested as an important source of fuel in many parts of the world. By volume, there are about 4 trillion m³ of peat in the world covering a total of around 2% of global land area (about 3 million km²), containing about 8 billion tera joules of energy. Over time, the formation of peat is often the first step in the geological formation of other fossil fuels such as coal, particularly low grade coal such as lignite.

Peat Mining in Europe for Power Generation

- Peat has been used as a form of energy for at least 2 000 years. It was useful as an alternative to firewood for cooking and heating in temperate and boreal regions of Europe, in particular Ireland, England, the Netherlands, Germany, Sweden, Poland, Finland and the USSR.

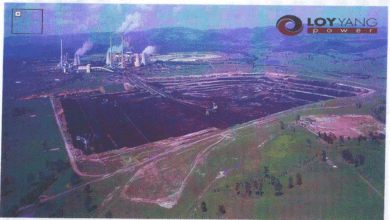

- Peat appeared especially competitive in the 60-200 MW power plants which necessitated the reclamation of vast areas of peat for large scale peat extraction, particularly in Ireland, Finland and the USSR.

Peat for Power Generation in Ireland, Finland and Russia

- The Electricity Supply Board of Ireland has been using Peat-fired boilers for electricity generation ranging from 20 MW to 40 MW for many years.

- Russia and Finland have set up power stations with capacities from 154 MW to 1020 MW.

Peat Fuel of Canada & Europe

- Canada contains over 170 million hectares of peat lands, the largest area of any country, and about 40% of the world’s peat lands.

- Finland with 10 million hectares and Ireland with only 1.2 million hectares have flourishing peat fuel industries.

- In Europe, peat fuel is produced in Finland, Ireland, Sweden, Latvia, Estonia and Lithuania with average annual production exceeding 3,200 ktoe (thousand tonnes of oil equivalent).

Hosaf Program for 20 MW Peat-fired Power Plant Using Madaripur Peat

- Exploration and Mining Lease are to be taken from BMD

- Area to be leased for exploration and mining: 5000 hectare = 50.0 km2

- First Phase: Exploration Lease = 2-years [2014-2015]

Major Works During Exploration Lease:

- Drilling 25 holes in one sq. km. area (hole dia 3-4 inch, hole depth 15-20 ft).

- Drilling by Hand Auger Drill Machine.

- Total number of holes to be drilled = 1250;

- Six holes to be drilled by one auger m/c per day (8-hours);

- 3-labour in one hole; 1-geologist and 1-driller/supervisor with one auger;

- Tk 800/- to Tk 1000/- labour cost for one borehole.

- Interval between two holes = 250m;

- Collection of samples from each hole;

- Testing and Chemical analysis of the samples;

- Reserve estimates and demarcation of peat area for mining;

- Preparation of Techno-Economic Feasibility Report;

- Applying for Mining Lease;

- Second Phase: Mining Lease = 10-years [2016-2026];

Major Works during Mining Lease:

- Develop the area for mining;

- Develop the site for peat drying;

- Develop the site for installation of power plant;

- Installation of Equipment for Mining;

- Installation of Peat-fired Power Plant;

- Peat Production = 0.5 million tons per anum;

- Power Generation = 20 MW;

- Estimated Cost of Power Generation at Peat site = 5cents / kWh.

- Immediate Tasks:

- Selection of Site.

- Locating Exploration Area.

- Collection of Toposheet of Madaripur and Faridpur from Survey of Bangladesh.

- Pin-Pointing Exploration Area in Madaripur Mouza Map.

- Applying to BMD for Exploration Lease.

Cost of Peat fired Power Plant:

- 150 MW capacity Peat-fired Power Plant, based on fluidized bed combustion technology with 40% efficiency, costs 225 million euro (1500 euro/KW) in European countries during 2008.

Cost of Coal fired Power Plant:

- 500 MW capacity Coal-fired Power Plant, based on pulverized coal combustion technology with 42% efficiency, costs 650 million euro (1300 euro/KW) in European countries during 2008.

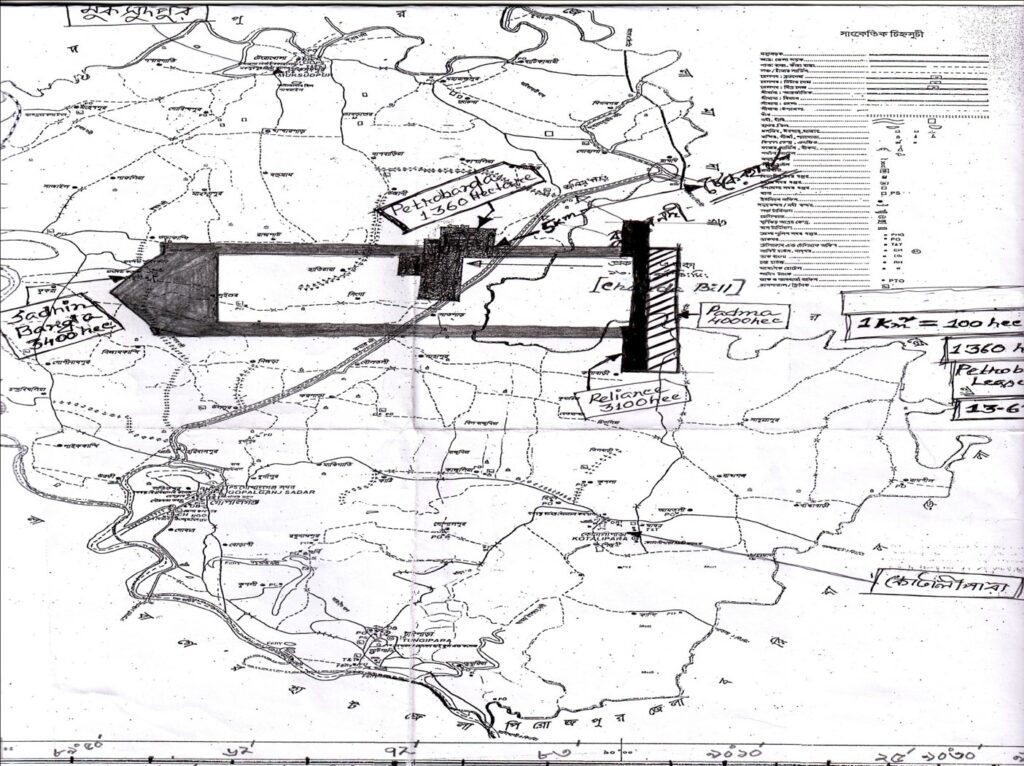

Peat Exploration License Program of Padma Mining Corporation

- Padma Mining & Energy Corporation Ltd, a private mining company of Beximco Group, has taken exploration lease, in the name of 3-different Farms, for a period of 3-years (2011 – 2013) from Bureau of Mineral Development (BMD) for Exploration of Peat Deposit in Baghia-Chanda Beel under Madaripur district as follows:

- Padma Mining – 4000 hectare – 40.00 sq. km.

- Shadhin Bangla – 3400 hectare – 34.00 sq. km.

- Reliance Ltd – 3100 hectare – 31.00 sq.km.

- Padma Mining and Energy Corporation have planned to drill about 3780 boreholes at 200m apart (each borehole of 3 inch diameter and 15 feet deep) covering an area of 105 sq. km i.e. 10,500 hectare [36 holes in 1.0 sq.km. area] to collect peat, soil and water sample. All related tests and chemical analysis of the samples are to be done in Bangladesh.

Peat Exploration License by Petrobangla

Petrobangla has undertaken an exploration license from Ministry of Energy for Peat Exploration in Baghia-Chanda Beel covering an area of 1360 hectare (13.6 sq.km) in 2012. Petrobangla has not yet started any physical work.

Recommendations

- It is recommended to take up the scheme for installation of 20 MW power plant either at Madaripur (Chanda-Baghia Bill) / Khulna (Kola Mouza) area.

- A visit to these two sites are required to be made in order to locate final site for peat exploration and mining.

- After site selection – a formal application for exploration license is to be submitted to BMD.