Chapter 22

Engr. Abul KM Shamsuddin’s Proposal in 2015 to Govt. of Bangladesh

for Generation of 300-1000 MW of Electricity using Khalashpir Coal by 2022.

A presentation by:

Engr. A. K. M. Shamsuddin

Project Director,

Khalashpir Coal Mine TEFS Project,

&

Petroleum & Mining Consultant,

Hosaf Group of Companies,

Dhaka, February 2015.

- Power System Master Plan 2010 details out the planning for the future coal fired power stations in Bangladesh.

- Of the 33,708 MW power requirements by 2030, the Govt. of Bangladesh plans to generate 20,000 MW using coal from both domestic and imported.

Power Demand Forecast;

Govt. Policy Scenario

|

Year |

Peak Demand [MW] |

Generation [GWb] |

|

2015 |

10,283 |

54,047 |

|

2016 |

11,405 |

59,945 |

|

2017 |

12,644 |

66,457 |

|

2018 |

14,014 |

73,658 |

|

2019 |

15,527 |

81,610 |

|

2020 |

17,304 |

90,950 |

|

2021 |

18,838 |

99,838 |

|

2022 |

20,443 |

109,239 |

|

2023 |

21,993 |

118,485 |

|

2024 |

235,811 |

128,073 |

|

2025 |

25,199 |

137,965 |

|

2026 |

26,838 |

148,114 |

|

2027 |

28,487 |

158,462 |

|

2028 |

30,134 |

168,943 |

|

2029 |

31,873 |

180,089 |

|

2030 |

33,708 |

191,933 |

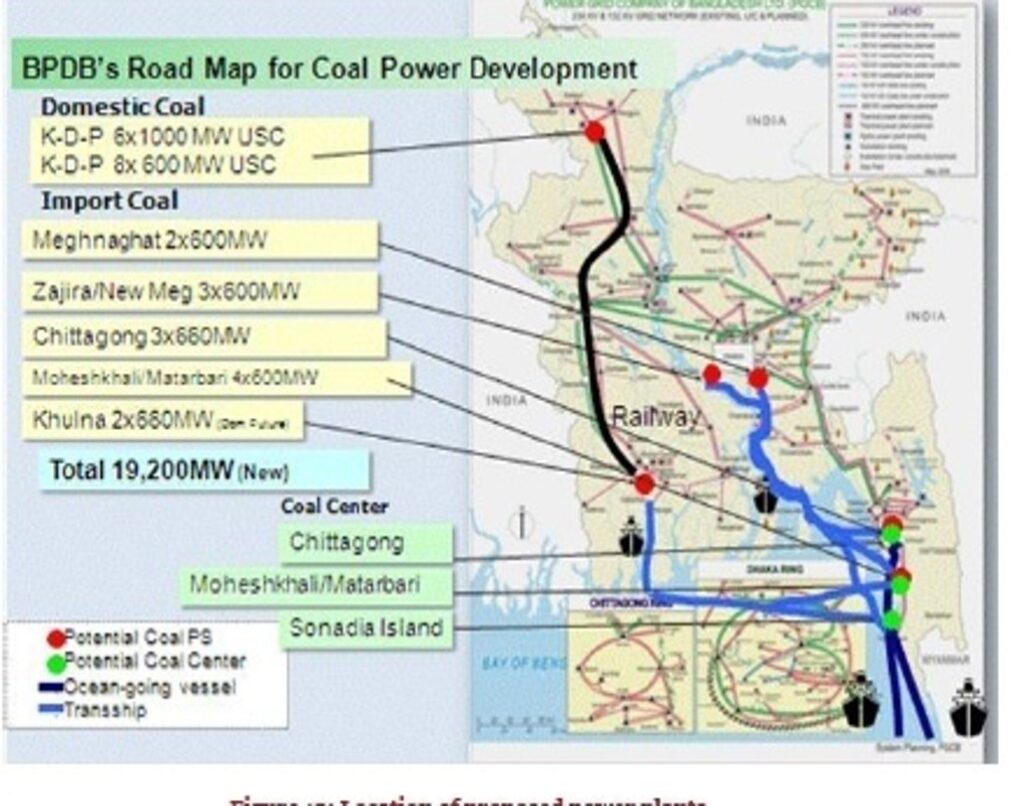

Coal Fired Power Generation Projects Planned by BPDB (up to 2030)

|

Domestic Coal Based |

||

|

K-D-P |

6*1000 MW USC |

6000 MW |

|

K-D-P |

8*600 MW USC |

4800 MW |

|

Sub Total (local) |

10800 MW |

|

|

Imported Coal Based Rampal, Khulna |

Khulna 1300 MW coal based TPSC Project |

660*2=1320 MW |

|

Anwara, Chittagong |

Chittagong 1300 MW Coal Based TPSC Project |

660*2=1320 MW |

|

Mosheshkhali, Cox’s Bazar |

Mosheshkhali 5320 Coal Based |

1000*4=4000 MW |

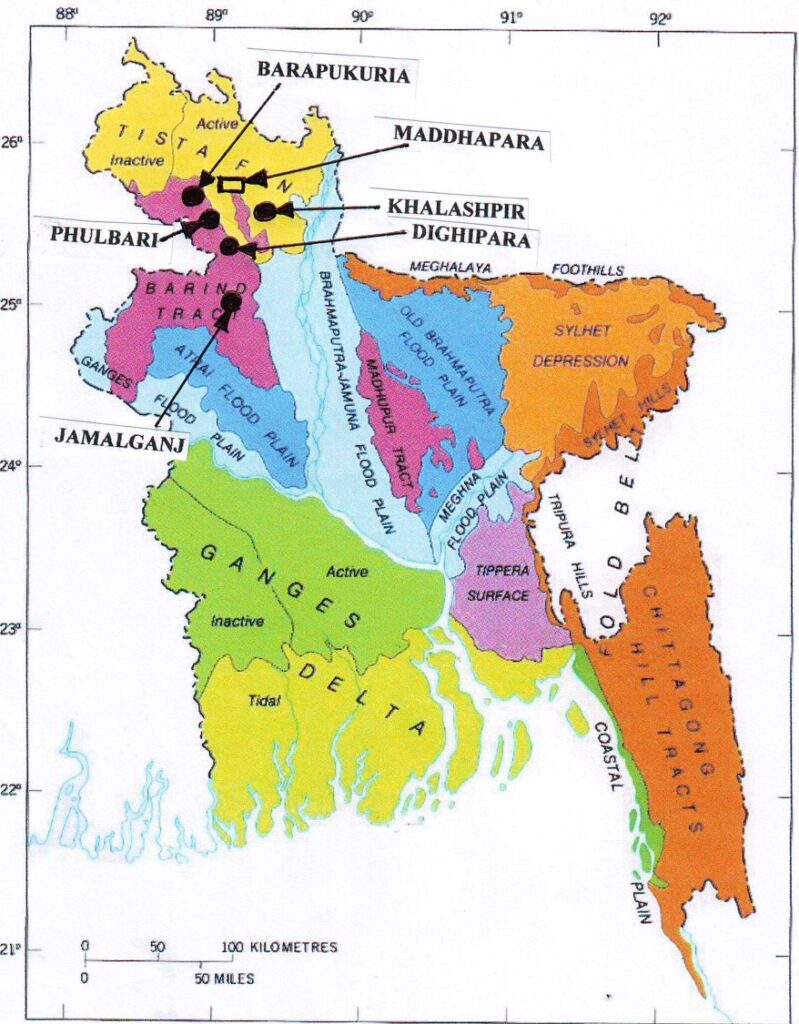

- The Road Map shows:

- Domestic Coal based power generation from Khalashpir – Dighipara – Phulbari up to 2030 will be:

- Phase – 1: 6X1000 MW = 6,000MW

- Phase – 2: 8X600 MW = 4,800 MW.

Out of above, 300 MW and then 1000 MW electricity can be generated from Khalashpir Coal by 2022 & 2026.

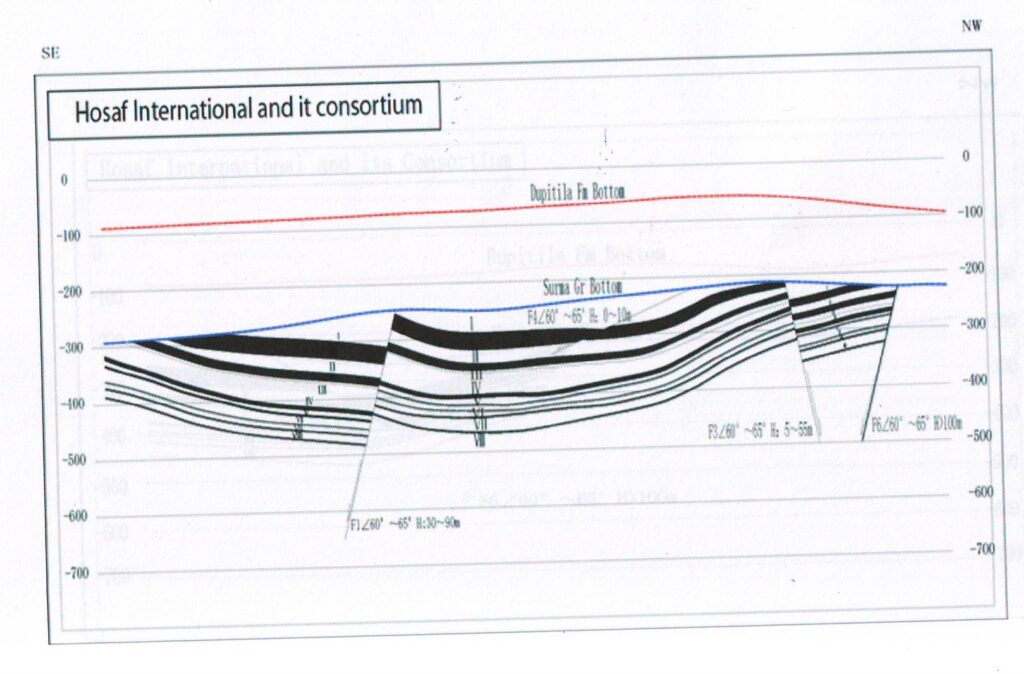

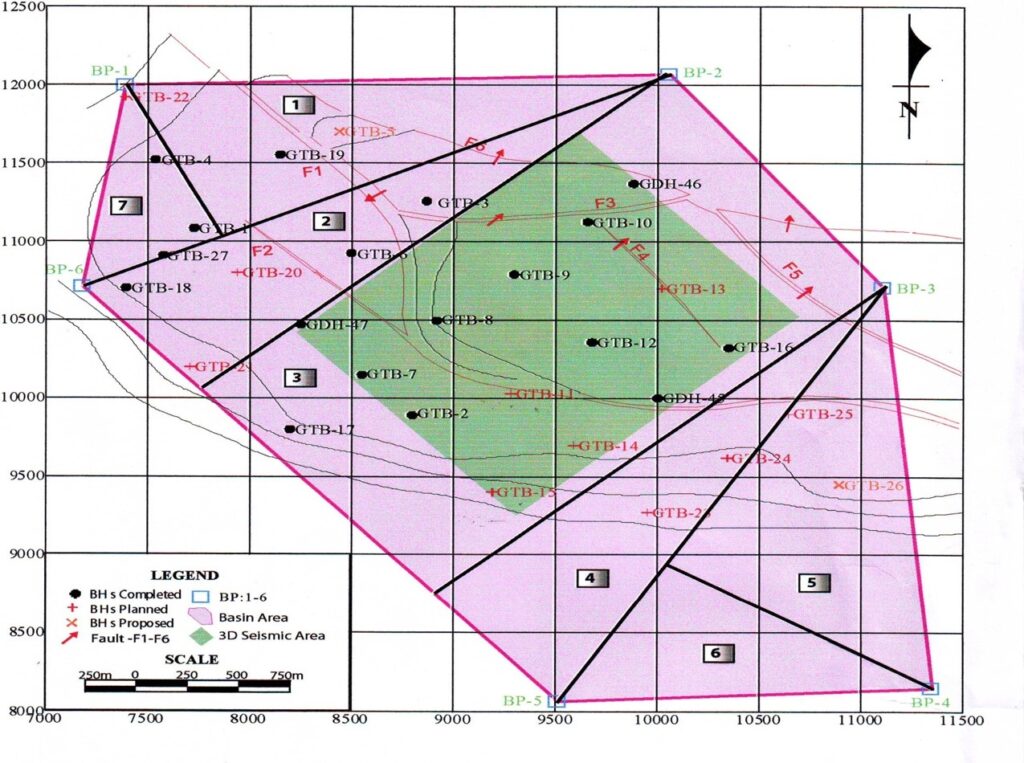

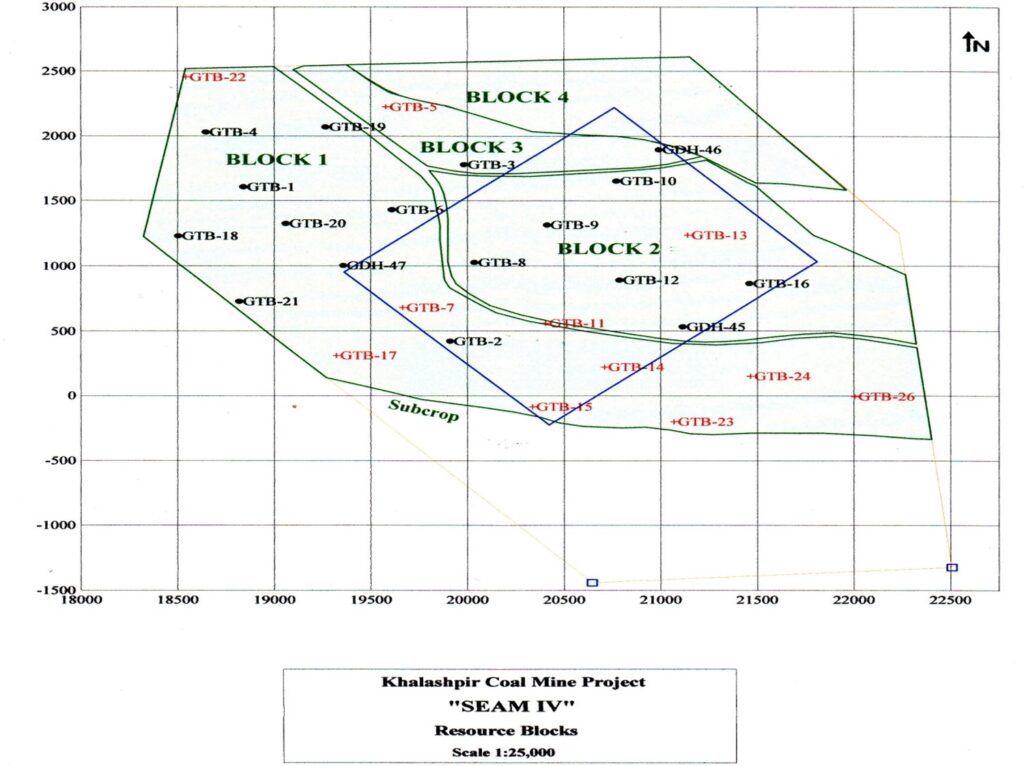

TEFS of Khalashpir Coal Deposit By Hosaf Consortium: 2D Seismic Survey

- High resolution 2D seismic survey was conducted covering an area of 12.25 sq.km.

- Total completed length of 2D survey length is 45.3 LKM.

- Survey grid = 500m X 500m

- Total Survey Lines = 12

- Total Shot Points = 1911

- Interval between two seismic lines = 500m

- Interval between two shot holes = 20m

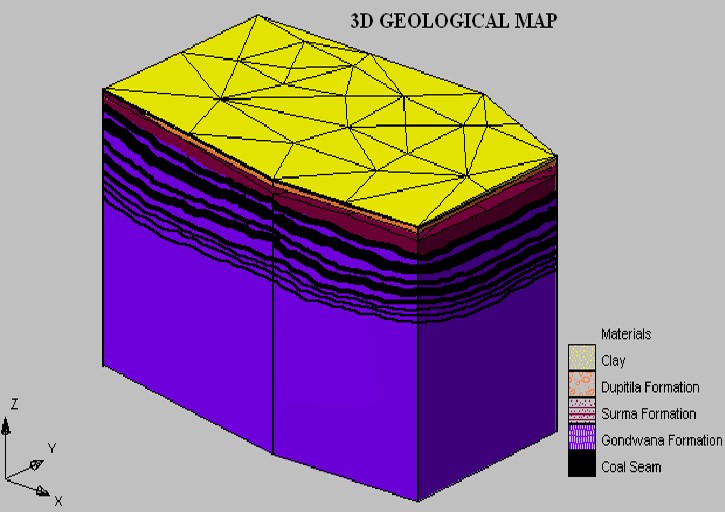

3D Seismic Survey at Khalashpir Coal Basin

- Total area covered under 3D seismic survey = 3.0 sq. km.

- Survey grid = 20m X 40m

- Total shot points = 3117

Thus a total of 5028 shot holes were drilled under 2d & 3d seismic survey in the Khalashpir Coal Basin Area.

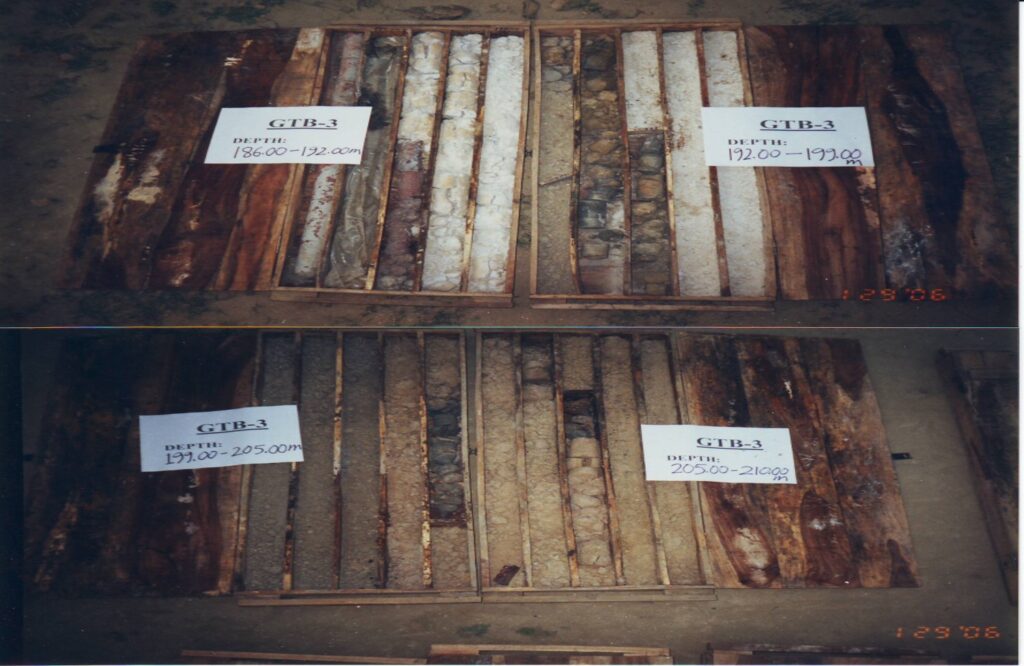

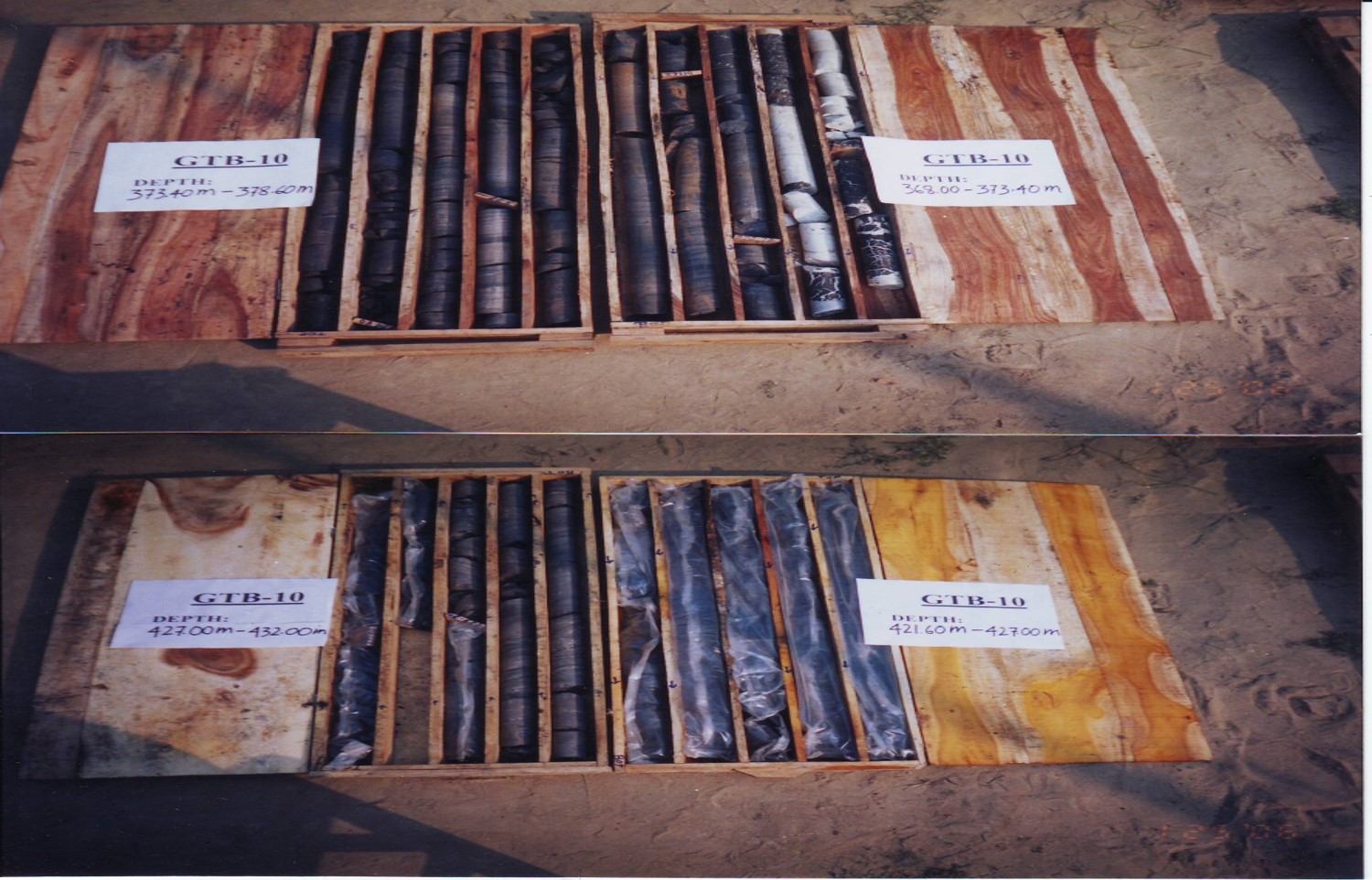

Exploration Drilling at Khalashpir Coal Field

- 4 (Four) boreholes were drilled by GSB in 1989.

- 3-GSB boreholes struck coal at Khalashpir.

- A total of 14 boreholes were drilled by Hosaf Consortium covering coal basin area of 12.25 sq. km. All the holes penetrate coal seams.

- The depth of the boreholes ranges from about 350m to 500m.

- During the course of drilling eight (8) coal seams were encountered at depths ranging from about 240m to 480m.

Salient Features of Techno-Economic Feasibility Study of Khalashpir Coal Deposit

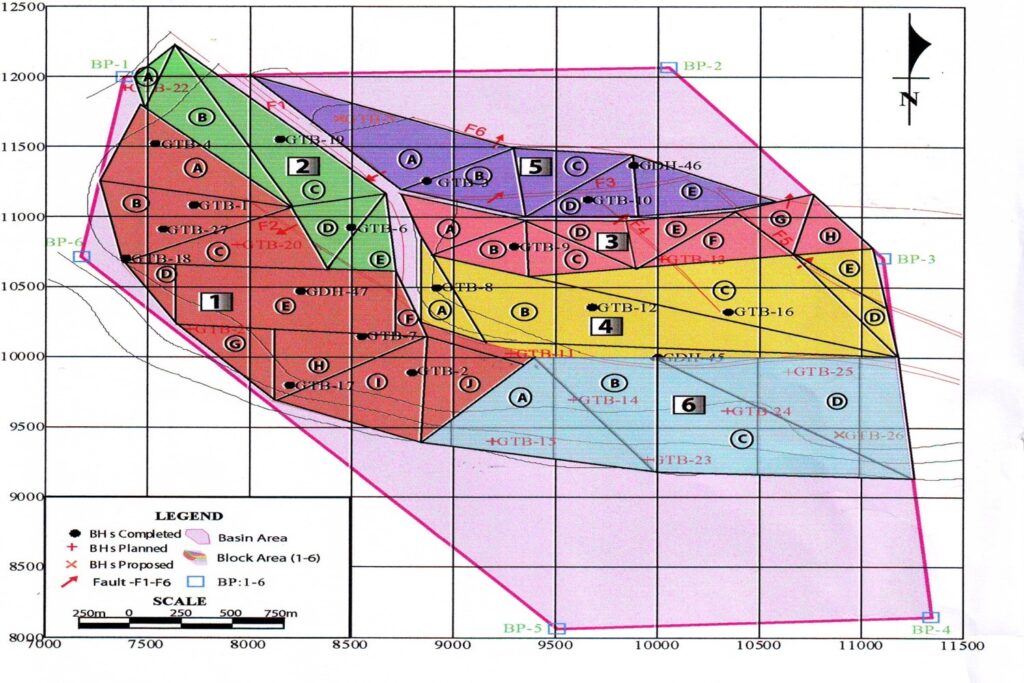

- Exploration licensed area: 25.00 sq.km.

- Coal basin area: 12.25 sq.km.

- No. of coal seams: 8 (eight).

- Total coal reserve: 451.00 million tons (7.5 sq.km).

- Measured reserve: 277.00 million tons.

- Coal type: High Grade Bituminous Coal.

- Coking coal: 26.70 million tons.

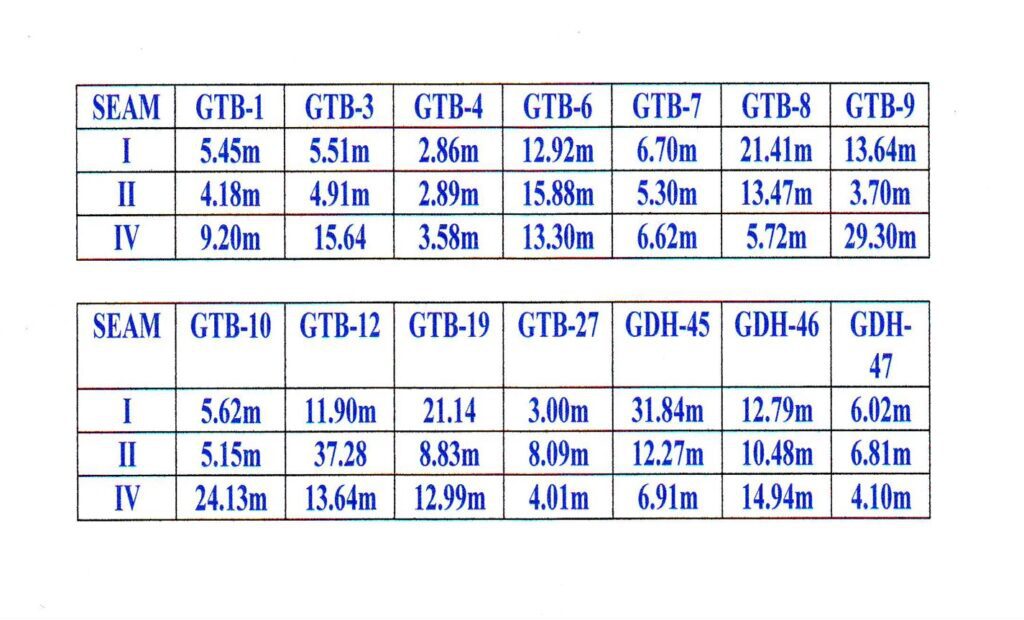

- Proposed mining of seams: Seam 1,2 & 4.

Thickness of the coal seams:

Seam-1 = 5.45m to 31.84m

Seam-2 = 4.18m to 37.28m

Seam-3 = 0.12m to 6.67m

Seam-4 = 4.01m to 29.30m

Seam-5 = 1.42m to 8.84m

Seam-6 = 1.20m to 9.50m

Seam-7 = 0.10m to 11.82m

Seam-8 = 0.20m to 6.85m

- Mining method: Underground Longwall.

- Initial production: 2.00 million tons from year 2022 generating 300 MW of Power.

- Full production: 4.00 million tons in 12th year generating 1000 MW of Power.

- Mine construction & development period: 5-years (five) years.

International Mining Consultants Ltd (IMCL) Evaluation of Khalashpir TEFS

- IMC Group Consulting Ltd of U.K. evaluated the TEFS of Khalashpir Coal Deposit, briefly, as follows:

- Generally a good quality of data has been acquired, but the sequence of coal seam stratigraphically is likely to be variable.

- Resolution of seismic data is up to satisfactory level to identify major structures and fault displacements greater than the seam thickness, therefore adequate for mine planning.

- Seven normal faults have been identified by the seismic surveying, trending generally sub-parallel to the NW-SE synclinal axis. The three largest faults in the TEFS Report are interpreted with maximum vertical displacements in excess of 50m.

- IMC Gr. Conducted preliminary estimate of resources in seam 1, 2 & 4 as follows following JORC’s code of estimation:

- Seam – 1 = 76.67 million tons; Seam – 2 = 140.97 million tons; Seam – 4 = 119.66 million tons;

- Due to geological, hydro-geological, and geo-technical environment and considering depth of 1st seam which is about 250m below the surface – IMC Group agreed with TEFS Report to adopt underground method of longwall mining with sub-level or top coal caving for Khalashpir Coal Deposit.

- IMCL recommended for adequate exploration drilling with borehole interval less than 500m.

UNFC Classification by PwC

PwC estimated an indicated coal resources to the tune of 297.57 million tons over an area of 7.5 sq. km. adopting UNFC Classification System on the basis of data and information from TEFS of Khalashpir Deposit & findings from IMCL evaluation.

- According to TEFS of Khalashpir Coal Deposit, 17-boreholes were drilled covering an area of 12.25 sq.km.

- Spacing between two holes were 500m.

- This makes borehole density of 1.4 per sq. km.

- Since exploration drilling were inadequate, PwC puts whole coal resources into “Indicated Category” under UNFC Classification.

- Now to convert this Indicated Resource Category into Measured Resource Category, it is recommended by Hosaf Gr. to conduct drilling of another 10 boreholes over 7.5 km2 area making a borehole density of 3.6 per square kilometer.

- High Resolution 2D Seismic Survey over 12.25 sq.km. area is also recommended.

- A time frame to conduct seismic, drilling, geo-physical logging, chemical analysis of coal, hydro-geological investigation, geo-technical investigation, EIA & SIA of the Coal Mine is being suggested as follows:

- 2D Seismic Survey = July 2015 – December 2015;

- Exploration drilling of 10 boreholes = July 2015 – June 2016. (Spacing between 2 holes = 250m);

- Geo-physical logging, chemical analysis, geo-technical investigation = January 2016 – June 2016;

- Hydro-geological test/pump test, EIA & SIA = July 2016 – June 2017;

- Mine Construction & Development = July 2016 – June 2021 (5-years);

- Bye Product from Shaft & Roadway = 1.00 million tons from January 2021.

- Commencement of Production 2.00 million tons = January 2022. (Generation of 300 Mw of Electricity from 6th year).

Power Generation From Khalashpir Coal Mine by January 2022

By implementing the above programme 2.00 million tons of coal may be produced from Khalashpir Coal Mine from 6th year i.e. by 2022 generating 300 MW of electricity and then 1000 MW from 12th year i.e. by 2026.

Conclusion – 1

- Khalashpir Coal may be utilized for generation of 300-1000 MW electricity – initially from year 2022 by installing mine mouth power plant.

- Hosaf-Chinese Consortium may be granted Mining Lease for 30-years for Coal Mine Development, Coal Production and Power Generation.

- First two years of Mining Lease will be used for 2D seismic survey, additional borehole drilling, related tests and EIA as per suggestion/evaluation of IMCL and PwC.

Conclusion – 2

- From the 3rd year of Mining Lease – Mine construction, mine development, coal production will be started.

- Subsequently initial power generation will be commenced from the 6th year of mining lease under a separate contract with GoB/PDB.

- Khalashpir Coal Field, having substantial deposit of high grade bituminous coal, with high calorific value, low ash content, low moisture content – in comparison with Barapukuria & Phulbari Coal Mines – should be immediately developed.

Conclusion – 3

- GoB planned to generate electricity through coal fired power plant by imported coal shortly. We strongly recommend to use domestic coal as well with imported coal for power generation.

- Khalashpir Coal, Phulbari Coal, Barapukuria Coal can be used for power generation.

- Simultaneous use of imported coal & domestic coal will greatly reduce cost of electricity generation.

Conclusion – 4

- Though the Govt. of Bangladesh plans to generate 20,000 MW using coal from both domestic and imported – out of 33,708 MW power requirements by 2030 as per Power System Master Plan-2010, we recommend it to start asap thus reducing overall power generation cost.

- It may be mentioned here that Bangladesh Coal is better than Indonesian, Indian and Australian Coal in terms of heating value, ash content, moisture content, sulfur content, etc.