Chapter 7

PHULBARI COAL DEPOSIT : Dinajpur, Bangladesh.

Geological, Hydrological & Social Environment Not Favorable For Open-Pit Mining – [Year-1998].

[Details Reasoning’s of Not to Consider Open-Pit Mining have been mentioned by Engr. Abul KM Shamsuddin in his presentations].

INTRODUCTION

Asia Energy Corporation (Bangladesh) Pty Ltd (AEC) has a contract with GOB for the exploration & mining of coal in Northern Bangladesh. The contract was originally signed with Australian Mining Company BHP (now BHP Billiton) in August 1994. BHP explored the area during 1995-1997 & confirmed the presence of coal. BHP withdraw from the Project in February 1998 & assigned the contract to Asia Energy. GOB formally endorsed the assignment to Asia Energy in February 1998. AEC’s Phulbari Coal Project is located in Phulbari, Dinajpur district.

ABSTRACT

- Asia Energy Corporation (AEC), a U.K. based Global Mining Company, submitted a proposal to the Govt. of Bangladesh to exploit Phulbari Coal adopting Open-Pit Mining Method.

- But the geological, hydrological & social environment of Phulbari Coal Basin is not favorable for open-pit mining method.

- Existence of most potential & major groundwater reservoir of north-western region of Bangladesh above the coal seam, then unconsolidated, incompetent, waterlogged overburden over the coal bed and agricultural land, townships, villages, forests, graveyard, mosques,etc. at the surface put the conditions unfavorable for open-pit mining.

- Exploitation of Phulbari Coal adopting underground mining method with suitable technology will be advantageous over open-pit mining method.

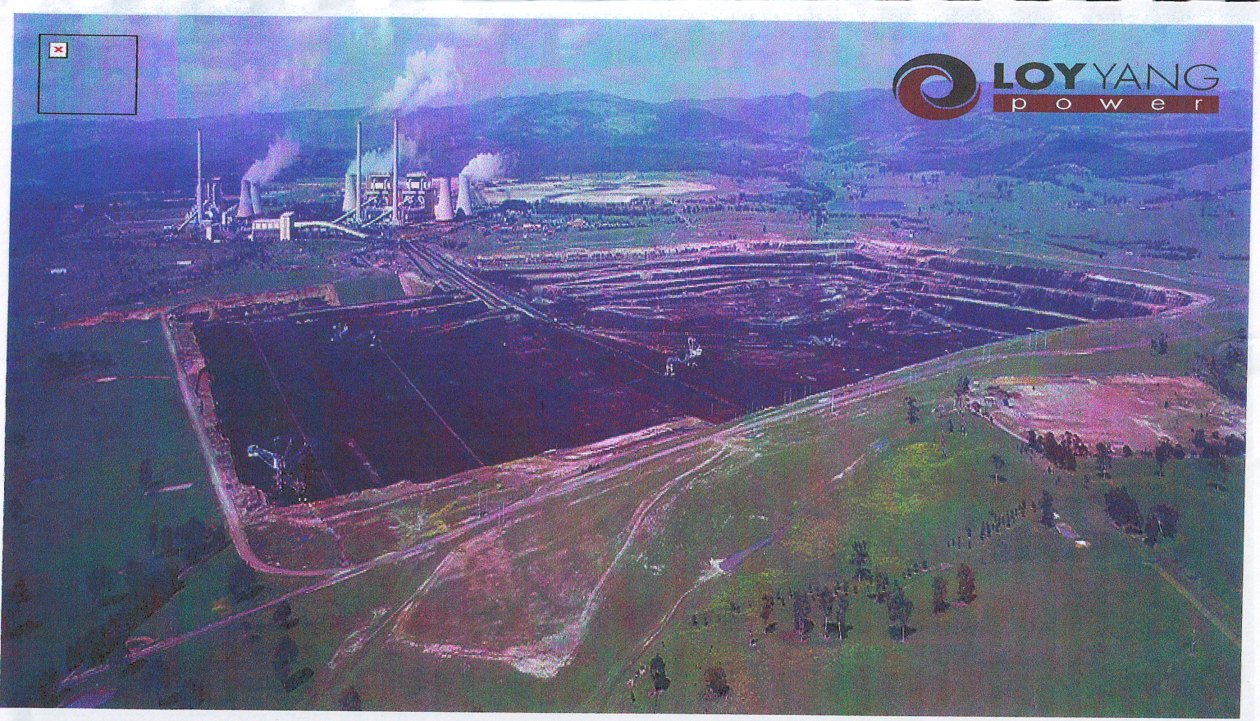

Loy Yang Open-Pit Coal Mine & Power Station, Melbourne, Australia

- Yearly Coal Production = 31.00 Million Tons

- Power Production = 4 x 500 MW PS Units = 2 x 500 MW PS Units

- Mine Size = 2 km x 3 km x 160 m deep (current) = 3 km x 6 km x 210+ m deep (future)

- Life of Mine = 50+ Years

Exploration in Phulbari Region-1

- GSB discovered Gondwana sediments, drilling south of Phulbari in 1960.

- Regional gravity program in the Dinajpur-Rangpur region by GSB between 1977-1978.

- Petrobangla/Wardell Armstrong made feasibility study of Barapukuria Coal conducting extensive high resolution seismic reflection survey and drilling in 1990. The seismic reflection traverses extended into the BHP/Asia Energy license and lease areas indicating the potential for coal in the Phulbari area.

- Regional coal exploration (gravity, seismic reflection, drilling) undertaken by BHP between 1995-1997 leading to confirmation of Phulbari Coal Deposit.

Exploration in Phulbari Region-2

- Asia Energy completed limited gravity survey in 1999-2003,intregrated with previous GSB gravity survey of Barapukuria. Re-interpretation of BHP seismic and limited follow up basin margin definition drilling on the western and northern section of the Phulbari Basin in October-November 2003.

Asia Energy’s Intensive Field Program (2004-2005):

- 2,370 new gravity stations and 864 previous gravity stations have been incorporated into new updated Bouguer anomaly and residual gravity maps of the Phulbari and Barapukuria Coal Basins & surrounding areas assessment of the extent of the coal basin.

Exploration in Phulbari Region-3

- 98.5 km of magnetic survey for basin definition.

- Reprocessing & reinterpretation of BHP seismic lines & reinterpretation of southern portion of Barapukuria seismic survey to enhance basin structural interpretation.

- Electromagnetic resistivity profiling surveys of rivers & proposed diversion routes to map clay cover.

- Geophysical borehole logging by Bangladesh Atomic Energy Commission (BAEC).

- 108-Exploration boreholes which includes for coring, open hole drilling, hydrogeological investigations, aquifer tests, groundwater observation boreholes, etc.

Phulbari Coal Project Location

- Phulbari coal mine project located within Phulbari, Nawabganj, Birampur & Parbatipur Upazilas under Dinajpur District in the NW region of Bangladesh. Project site is 350 km away from Dhaka & connected with road & rail.

- The surface area of the project contains agricultural land, villages, township, forests, mosques, graveyards, roads, railways.

- The below ground area contains regionally extensive groundwater resource overlying the coal.

Geology & Hydrogeology of Phulbari Coal

Geologically rock strata sequence of coal basins in NW Bangladesh are divided into 4-formations based on age and lithology:

- Madhupur/Barind clay (10-12m thick) from recent Holocene era

- Water-bearing DupiTila aquifer of Late Miocene-Middle Pliocene age

- Permian coal-bearing Gondwana rock sequence

- Pre-Cambrian Archean basement.

The Dupi Tila Aquifer has two formations: The Upper Dupitila & The Lower Dupitila.

- The Upper Dupi Tila Formation (UDTF) consists of sandstones, siltstones, minor clay. UDTF is unconfined mega-aquifer covering entire northern districts & main source of drinking water, irrigation & other utilities. Thickness ranges from 95-126m in Barapukuria coal basin and upto 125m in Phulbari coal basin.

- The Lower Dupi Tila Formation (LDTF) consists mainly of loose clay with mica, pyrite & chalcopyrite minerals. The maximum thickness of LDTF in the Barapukuria coal basin is about 80m to southern part but absent in northern part. In Phulbari coal basin, the thickness of LDTF is about 30m.

Geophysics of Phulbari Deposit

- The gravity survey of Phulbari & Barapukuria Coal Basins identified limits of the Permian Coal basins, locations of the faulted eastern margin and identified structural trends.

- Two structural trend directions – NNE to SSW & WNW to ESE – were detected.

- The basement depth derived from gravity has shown the coal basin to have evolved in several deeper basin compartments separated by relatively shallow basement (such as between Phulbari & Barapukuria basins). Fault control has been inferred in structural analysis. (from modelling of basement depth).

- Ground magnetic survey indicated some upper permian and basement rocks were magnetic.

- Faulting is particularly marked and complex in the south of Phulbari basin.

- Seismic data helped in detail structural analysis of the basin.

- Resistivity mapping by electromagnetic methods, of shallow resistivity in the riverbeds and proposed river diversion routes has indicated likely areas of shallow or exposed aquifer sands amenable to greater recharge of the aquifer.

Geology & Hydrogeology of Phulbari Coal

The Permian age coal bearing Gondwana Formation in Phulbari coal basin contains 11-coal seams in 5-coal horizons. Individual coal seam thickness varies from 20-40m with a cumulative total thickness upto 73-meters. BHP/AEC discovered 572.00 million tons of high quality bituminous coal at a depth of 250 meters from the surface at Phulbari.

Aquifer Characteristics of NW Region

Major & Most potential groundwater reservoir of Bangladesh lies in the north-western region of Bangladesh. The Phulbari coal seams lie below this aquifer:

- Thickness of aquifer: 80-120m

- Type of aquifer: Extensive, unconfined, mega type, locally semi confined

- Transmissivity: High

- Lithology: Coarse piedmont deposits, silt clay

- Remarks: Suitable for groundwater development

- Partial Arsenic Safe Aquifer:

- The Barind Tract is located in the west of Brahmaputra River. It falls in the central part of north Bengal and covers an area of 7680 sq.km. in the Rajshahi Division. The area comprises of six north-south elongated isolated exposure of reddish brown deposits. The Barind Tract is the product of vertical movements of Pleistocene period as maximum height of 20m above modern flood plains. The areas of greater Dinajpur district are covered by partially Safe Aquifers in the Barind Region.

Aquifer Characteristics of Phulbari Basin

- Madhupur Clay is soft, sticky, silty clay and restricts direct rainfall recharge to UDT. Its permeability is 0.0001 to 0.008 m/d.

- Little Jamuna River has cut down through the Madhupur clay into UDT is a significant source of recharge via stream leakage with leakage through the clay away from the river.

- Principal aquifer, the UDT, unconfined to semi confined, comprises medium to coarse sands, silty sands and basal gravels. Aquifer transmissivity ranges from 650 to 1500 m2/d with hydraulic conductivity 6 to 15 m/d. Storativity ranges from 0.001 to 0.0001 and specific yield 0.15 to 0.25.

- Depths to groundwater range seasonally from 2-9 meters.

- Groundwater levels in monsoon (June-October) rise to within 2 meters and irrigation drawdown lowers levels by approximately 7 meters. Groundwater flow direction in the UDL is from N to NE to S or SW.

- LDT is the regional aquiclude and present across Phulbari Basin, thickening towards center of the basin. LDT aquiclude reduce the potential for vertical groundwater flow between the UDT and Permian Units. LDT aquiclude is absent in the north of Barapukuria Basin.

- Sand layers identified at the base of LTD constitute significant aquifers, particularly in the south of the basin. 2-15m sand layer is confined by overlying grey-green organic clays 20-30m thick.

- Permian rocks (including coal bearing Gondwana Group) are confined by overlying LDT. Weathered zone developed at the upper section of the Permian will restrict vertical groundwater flow between Permian & Tertiary units and provide further confining conditions on the underlying coal sequence. Hydraulic conductivity of 0.04 m/d and storability of 5×10-3 have been determined for the weathered zone.

- Coal sequence comprises an upper, middle, and a series of smaller lower seams. Coal sequences are highly jointed with sub-horizontal and sub-vertical joints visible. Hydraulic testing of Permian sequence at Barapukuria suggests coal seams have a higher permeability than intervening sandstone & mudstone beds. Experience from Barapukuria suggests roof & floor sandstone could form significant aquifers.

- Degree & orientation of faulting and fracturing control groundwater flow horizontally and vertically within Permian rocks. Hydraulic conductivity of 0.3 m/d and storativity of 1X10-5 have been estimated for coal seam and coal roof sequence.

- Groundwater flow within coal sequence will be from north to south along the axis of the basin. Groundwater inflow from Barapukuria Basin to north is expected and groundwater will flow southerly in continuation of the Permian formation beyond Phulbari Coal Project area.

- The Basement Rocks are generally massive i.e. not well fractured and are therefore not considered to be aquifers.

Phulbari Basin Hydrogeological Model

- Leakage from the river systems and overlying Madhupur Clay are significant groundwater recharge mechanisms across the region.

- Dewatering of UDT sand to be done within the required time frame for excavation of mine box cut. LTD require dewatering during initial stages of mine development to assist slope stability.

- Continuous groundwater extraction rates up to 7,000 liters/second will be required to manage groundwater over the life of the mine.

- Indicative UDT groundwater level drawdown radially from the mine is estimated to be 70 to 90m at the crest; 30-40m at 3 km; 10-15m at 5 km and 1-5m at 10 km.

Physical Characteristics

- Phulbari project located on the Barind Tract, in the plateau region with a height of 25-32m above sea level. Average temp range from 33 degree celsius in summer to 10 degree celsius in winter. Rainfall occurs between May & October, average rainfall being 1800 millimeters.

- Coal basin surrounded by Little Jamuna river to west & Khari Pul & Nalsissa river to the east. Khari Pul river drains into Ashoorar Beel an important wetland and local fishery.

Key Parameters of Phulbari Coal

- Coal Reserve:

- Measured: 288.0 Million Tons

- Indicated: 244.0 Million Tons

- Inferred: 40.0 Million Tons

- Rank of Coal: High Volatile Bituminous

- Depth of coal from surface: 250-300 meters

- Number of coal horizon: 5 (five)

- Thickness of individual coal seam: 20-40 meters

- Cumulative Thickness: 73 meters

- Mining Area: 59.33 sq.km / 5,933 hectares

- Average coal quality:

Moisture: 2.7%; Ash: 6.5-19%; Sulphur: <1.0%;

Sp. Energy: 6,600 Kcal/kg; 11,800 BTU/lb

- Life of Mine: 36-38 years

- Mine operation:

Mine Type: Open-cut, Truck, Shovel

[Open-cast based on conventional truck & shovel operations. The cut will be terraced to allow access for tracked excavators, front-end loaders, bulldozers and trucks. And to make roads on which coal and overburden will be hauled to surface].- Coal Extraction: Maxm 16.0 million tons/year

- Waste Rock: 7.1 : 1.0 waste bcm/ton of coal

- Civil Works: Construction, Rail Spur, Realignment of Roads, Rail, River.

Phulbari Coal Mine Footprint Area

- Mine Pit = 2,180 hectares = 21.80 sq.km

- Mine Pit = 2.80 km X 7.80 km

- Overburden Dump = 14.65 sq.km=2.0kmx7.3km

- Mine Infrastructure Area = 5.13 sq.km

- Infrastructure & Buffer Area = 10.34 sq.km

- Total Mining Area = 5192hec; 51.92 sq.km

- Town & Village Relocation = 6.62 sq.km

- Rail & Road Corridor = 79 hec = 0.79 sq.km

Grand Total = 5933 hectares = 59.33 sq.km (1.00 hect=2.47acre)& (1.00sq.km.=247 acre).

Habitat Within Mine Footprint

- Cultivated Land: 4,166 Hectares (ha)

- Homestead Vegetation: 666 Hectares

- Roadside Vegetation: 82 Hectares

- Exotic Plantation: 196 Hectares

- Wetlands: 82 Hectares

TOTAL: 5,192 Hectares (ha)

Environmental Impacts of Phulbari Mining

A] Soils, Land Use and Land Capability:

Potential impacts of mining on soils include:

- Water & Wind Erosion;

- Loss of structure through compaction;

- Depletion of nutrients, Weed infestation;

- Contamination from leaks and spillages.

- Mining will result in the loss of agricultural land and the landscape will change as a result of mining activities, extensive earthworks and the creation of a final landform, including the overburden dump and pit void.

AEC proposed to implement soil management plan, top soil management plan, erosion control measures, etc.

B] Climate Change:

Coal mining will result emission of greenhouse gases (GHG’s) including fugitive emission of methane (CH4) during mining operations and CO2 emissions from fuel combustion. The project’s overall contribution to GHG’s emission is relatively small. GHG management measures will be taken.

C] Air Quality:

Impacts on air quality will result from construction of infrastructure, overburden removal, coal mining activities and rehabilitation works. Cumulative impacts on air quality need to be monitored. Mitigation, control policies and procedures need to be enforced strongly. AEC predicts that the ambient air quality standard in the west of Coal Handling Preparation Plant (CHPP) & south of new Phulbari Township will be higher.

D] Noise:

There will be noise emissions from drill rigs, power generations, construction of transport corridors, mine infrastructures, mine operation equipment, blasting, coal extraction and transport to handling and storage facilities and earthworks and vehicle movements associated with rehabilitation of mine site. AEC observed that Project Noise Objectives in the residential areas closest to the mine may not be achieved. Detailed noise monitoring, regular assessment of noise impacts and process of environmental improvement will be adopted. Noise impacts from the operation of the Coal Handling Preparation Plant (CHPP) will be monitored and managed. AEC proposed that a noise mitigation earth bund extending around the rail loop and CHPP area will be placed as required.

E] Surface Water:

Hydrological and surface water quality characteristics could be affected by the construction of flood protection levees, overburden dumps and noise protection bunds, loss of water catchments areas, diversion of watercourses, and off-site discharge of excess treated mine site ‘dirty’ water. Potential impacts relate to discharges containing high sediment loads, low pH and elevated levels of nutrients, biochemical oxygen demand, chemical oxygen demand, oils and hydrocarbons. Changes to the physical/chemical environment of water bodies may have impacts on downstream aquatic flora, fauna and fisheries.

AEC proposes a sound ‘Surface Water Management Plan’ to mitigate the above surface water impacts.

F] Groundwater:

To maintain dry and safe working conditions in the open-cut mine, the water table will require lowering to the base of mine-pit. Dewatering will have potential impacts on the local and regional hydrogeological regime, with predicted groundwater drawdown of approximately 25, 15 and 10 meters at distances of 4, 6 and 10 kms from the mine pit respectively. This will result in reduction in groundwater availability to the farmers, township, villages, reduced baseline flow into water courses and Ashoorar Beel during dry season, land subsidence and a general reduction in groundwater quality.

Due to long term reduction in groundwater levels, groundwater drawdown have an impact on water levels in the beels and rivers by accelerating loss of base flow during dry season.

Other impacts include the potential for contamination of groundwater through leaks and spillage of fuel, oil or other chemicals during transport, handling, storage, and potential for contamination of groundwater by the Oxidation of Acid Mine Drainage (AMD) materials and the subsequent release of acidic water.

Though arsenic is not currently a problem in the Project area, there is a possibility of arsenic mobilization in the long term if coal rejects are mixed up with the Upper Dupi Tila (UDT) sediments.

Proposal of Asia Energy

- Extraction of 10-15million tons of coal yearly from a depth of 250-300meters by open-pit mining method during operational life of the mine which is 36-38 years.

- Removal of 4,400 million loose cubic meters (MLCM) of overburden (rock, sand, mud, soil) covering an area of 21.80 square kilometers during whole mine operation

Phulbari Pit Slope Design

- Groundwater drawdown and the Tertiary and Permian strength parameters are critical to slope stability and design aspects.

- Factor of Safety (FOS) against slope failure considered to be 1.1 to 1.3.

- FOS of 1.1 for individual batters and 1.2 to 1.3 for overall slopes were considered.

- FOS was calculated for local slopes in the UDT & LDT units at less than the thresholds outlined above.

- Little Jamuna River recharges the UDT aquifer. The existing river need to be managed to ensure that high ground water conditions do not impact on the stability of the western batters of the mine.

- This problem require compromise and management by partially lining river channel or provision of additional dewatering stations between the river and the mine crest.

Waste Dump Slope Design

- Normal dump height of 80m.

- AMD cell offset from batter crest of 60m.

- Cover above the AMD cell of 10m.

The strength of Modhupur clay and the phreatic surface within the external overburden dump has a major influence on the stability of the dump.

- Two dump configurations were considered:

- 18.5 degree/20m/20m [angle/berm width/batter height].

- 24 degree/40m/20m

With an overall height of 80 meters and angle of 15 degree.

Proposal of Asia Energy (cont)

- Coal seams of thickness between 20m & 65m are planned to be extracted from the upper & main coal seams.

- Mining operations consist – dewatering of aquifer, cleaning and top soil stripping, overburden removal, rehabilitation of mined out areas and overburden dumps.

- Aquifer dewatering will be continuous throughout the operation of the mine.

Aquifer Dewatering & Top Soil Stripping

- Deep dewatering tube wells to be installed in front of southward advancing mine. 80-100 de-watering wells operate at any one time. Aquifer injection wells to be installed 5-km from the pit & operates throughout the life of the mine to reduce the extent of water level.

- Top 20 cm topsoil will be stripped & stockpiled, but later be placed directly onto areas being rehabilitated. Sub-soil layer to be removed and separately stockpiled to facilitate placement back in the soil profile when required.

Overburden Removal

- 4,400 million loose m3 (MLCM) overburden to be removed over the life of the mine.

- Overburden to be used on-site for construction & rehabilitation or placed on the surface east of the mine (ex-pit) or in the mine (in-pit).

- Ex-pit dump extend over 1,465 hectares/14.65 sq.km & reach approximately 120m high.

- 30% of overburden to be dumped ex-pit and the remainder to be deposited back into the mine pit (in-pit).

Coal Mining Operation

- 5-Coal Horizons divided into 11-coal seams; thickness varies from 20-40m; cumulative thick ness being 73 meters.

- Coal from thick & extensive “Upper” & “Main” seams are to be extracted.

- Mining operations use a fleet of dozers, hydraulic excavators, haul trucks. Most coals require blasting.

- Coal Mine move southwards at a rate of 200m / year. Depth of pit between 250-300 meters.

- Water lake of 696 hectares at the southern most end upon termination of mining.

Coal Handling & Treatment

- The geology and geometry of the coal deposit are ideal for truck and shovel mining operation.

- Coal handling and treatment includes crushing, conveying, treatment, stock-piling and exporting.

- Coal will be hauled from pit by truck to primary and secondary crushers.

- Following crushing, coal will be fed into conveyor to tertiary crusher and stockpiles near coal handling preparation plant (CHPP).

Rehabilitation of Mined & Dumped Area

- Rehabilitation as per Land Use Plan (fig:ES12).

- Native & agro-forests on rehabilitated ex-pit over burden dump.

- In-pit overburden dump and other disturbed areas contoured to pre-mining levels with development of sustainable agricultural pursuits.

- A final void up to 250m deep to be filled with ground water on cessation of dewatering.

- Final landform include 14 km long wildlife corridor from 120m high ex-pit O.B. dump.

Proposal of Asia Energy (cont)

- Groundwater ranging from 400 to 800 ML/day need to be discharged throughout operational life of the mine.

- In other words Groundwater to the tune of 7,500 liters/second need to be extracted to dewater Phulbari Basin for Mining.

- AEC will make available discharged groundwater to the tune of 100 to 250 ML/day for riparian use, river discharge purposes and water for coal fired power station.

- Out of 4,400 million m3 of overburden, 30% will be dumped ex-pit & rest into the pit.

- Mine would displace 40,000 people, 100 villages and part of Phulbari township.

- To maintain dry working condition in the open-pit mine, AEC will depressurize aquifers and aquitards.

- Due to the mine dewatering activities water level drawdown will form an irregular ellipsoidal shape with water level declines in excess of 10 kilometers from the mine.

- Severe drawdown of >15m affecting an area of 82 sq.km. in the central zone.

- Moderate drawdown of 10-15m affecting an area of 57 sq.km. in the middle zone.

- Low drawdown of 5-10m affecting an area of 71 sq.km. in the peripheral zone.

- Phulbari Drawdown will extend to Barapukuria Deposit.

- Subsidence around Phulbari Open-Pit Mine is anticipated due to large scale dewatering of UDT sand, aquifer depressurization of LTD sand and consolidation of clay formations.

- Subsidence will occur up to the drawdown zone i.e. 10 km distance from the mine.

Subsidence Assessment

- Subsidence around Phulbari open-pit mine is anticipated by AEC due to large scale dewatering of UDT sand, aquifer depressurization of LTD sand and consolidation of clay formations.

| Location | North of Mine | East of Mine | South of Mine | West of Mine | |

| Mine Crest | 2.0m | 2.0m | 2.0m | 2.0m | |

| 1km from Crest | 1.0m | 1.7m | 1.4m | 0.4m | |

| 3km from Crest | 0.2m | 1.0m | 0.3m | <0.1m | |

| 10kmfrom Crest | <0.1m | 0.1m | <0.1m | <0.1m |

- Drawdown at UDT is predicted to extend to over 10 km from the mine. Drawdown at the Mine Crest will be approximately 70m. Drawdown within 3 km distance from Mine Crest will be up to 40m. Upper Dupitila Groundwater level drawdown will be 10-15m within 5 km distance from mine. It will be less than 5m within 10 km distance from the mine.

Proposal of Asia Energy (cont)

- Drawdown would reduce groundwater availability to Phulbari town, surrounding villages, local communities within the given area of influence.

- Ground water discharge will also impact on biodiversity, wetlands and rivers in the surrounding areas.

- River diversion, re-alignment of rail & road would be made.

MINE WATER BALANCE

- Project will have excess water round the year.

- 400-800 ML/day of groundwater to be discharged into Little Jamuna River during wet season.

- Clean & treated water to 100-230 ML/day available for riparian use, river discharge purposes and coal fired power station.

- During dry season water available to supply irrigation for two crops by continuous water injection.

SURFACE WATER

- Phulbari Coal Mine to be protected from floods by a peripheral Project-Bund , consisting 3.0m high flood level, 120m high ex-pit over burden dump, 5.0m high visuals mounds and 15m high noise protection bunds.

- Cheri Pul River to be diverted east of the ex-pit OB dump. Diversion will incorporate in-stream habitat features like areas of slack and fast flowing waters and provision of ecological links such as such as fish passages, still pools.

- Water, with high suspended solids in the mine pit, over burden dumps, coal stockpiles, processing areas, noise bunds, levees & other infrastructures, to be collected & treated within Mine Footprint. Excess treated water to be released to the nearby water courses.

- During wet season, discharge of treated water is expected to have a negligible impact on water volume and quality of receiving surface water bodies.

GROUND WATER

- To maintain dry working condition in open-pit mine, aquifers require dewatering & aquitards need depressurizing.

- Due to dewatering, water level drawdown form an irregular ellipsoidal shape with water level declines in excess of 10-km from the mine.

- Reduce ground water availability to Phulbari township, surrounding villages & local firms.

- Groundwater drawdown will impact on bio-diversity, wetlands, rivers and cannels in the surrounding areas.

AQUIFER INJECTION

- Depressurization of Aquifer through a radial injection system (tube wells or infiltration trenches) , some 4-5 km away from mine, will help to control groundwater level.

- Water level drawdown due to dewatering is restricted between mine-pit & injection areas.

- Aquifer injection to be installed in a ringed configuration around 4-5km of the mine to keep Ashoorar, Mollar, Hashkola, Rambhadrapur Sal Forests (Bio-diversity conservation) protected from mine dewatering impacts.

WATER TO FARMERS/VILLAGERS/TOWNSHIP

- Reticulated water by large diameter pipelines & trenches/canals from mine dewatering system or by deep tube well will be supplied to above users.

- In the wet season, rainfall irrigations to be practiced.

- Sufficient water from the dewatering operation is available for the piped delivery system in the dry season (216 ML/day) for the irrigators. Irrigation system to be operated by the “Barind Multipurpose Development Authority” and NGO in partnership with Mining Company (AEC).

Summary of Mitigation Measures on Groundwater Impact

- Deep Tubewells (DTW) to be drilled to the base of UDT to supply reticulated water to affected villagers.

- Aquifer re-injection system will be introduced to minimize the regional draw down effect.

- Groundwater from the dewatering system will be the primary source of reticulated water supply to the extended Phulbari Township.

- Coal rejects will be selectively buried at the base of the in-pit overburden dump.

- Surface landforms will slope towards the final void lake, Ashoorar Beel, Little Jamuna or Khari Pul Rivers. Surface water carrying organic matter will flow into the lake in wet season.

PROFIT FROM PHULBARI COAL

- Asia Energy Corporation (AEC) earns US $ 900.00 Million a year at a price of coal of US $ 60.00 / ton.

- That is about US $ 27.00 Billion in 30-years.

- Govt. of Bangladesh gets 6% Royalty.

ECONOMICS OF PHULBARI COAL

- Capital Investment on Mine Development and Power Station Installation: US $ 3.00 Billion.

- Operating Cost (Mine & Power): $ 10.4 Billion.

- Project Generate in Economic Benefit to Bangladesh: US $ 21.00 Billion.

- Addition of 1% a Year ($0.7 billion / annum) to Gross Domestic Product of Bangladesh.

Phulbari Coal Investment & Operating Cost (Year-2006)

| Serial Number | Items | Initial Capital Cost$Mln | Mine Life Capital Cost$Mln | Initial Operating Cost$Mln | Mine Life Operating Cost$Mln |

| 1 | Open Cast Waste Removal | 303 | 1028 | 113 | 3116 |

| 2 | Open Cast Coal Mining | 28 | 171 | 24 | 542 |

| 3 | Open Cast Support | 31 | 171 | 22 | 685 |

| 4 | De-Watering | 44 | 87 | 14 | 436 |

| 5 | CHPP | 127 | 128 | 35 | 1028 |

| 6 | Mine Admn & Development | 64 | 96 | 8 | 265 |

| 7 | Resettlement | 255 | 314 | 7 | 177 |

| 8 | Owner’s Cost | 22 | 54 | 5 | 171 |

| 9 | Coal Transport | 43 | 43 | 74 | 2306 |

| 10 | Royalty | 56 | 1649 | ||

| Total | 917 | 2090 | 358 | 10,370 |

Hydrological Impact

- Main aquifer in the north-western region of Bangladesh is of 80m-120m thick and is situated at 10m-12m below surface at the Dupitila Formation over the Phulbari Coal Basin and Barapukuria Coal Basin.

- Groundwater in North-Western zone are almost arsenic contamination free.

- The underground water level in eight northern districts including Dinajpur falling gradually posing a threat to irri-boro farming. 30% tube wells have become inoperative in the area for want of water in UG level.

- A source said the water reserve in upper part of UG level has been exhausted & next level has gone down by 10-15 feet. The badly affected districts are Dinajpur, Rangpur, Thakurgaon, Kurigram, Lalmonirhat, Nilphamary & Gaibandha.

- The water reserve in those areas is shrinking & the lifting of water become impossible by thousands of shallow tube wells, low lift pumps, traditional pumps and deep tubewells. The small rivers, beels, haors, ponds are drying up.

- As per an NGO, northern region including Barendra Bhumy will turn into a desert if water lifted from UG exceeds 15000 cusecs a year. At present 1,00,000 cusecs are being lifted which is alarmingly higher than the red signal.

Dhaka Close to Environmental Disaster

Dhaka stands today perilously close to an environmental disaster with concentration of Nitrogen Dioxide, Sulphur Dioxide and Suspended Particulate Matters (SPM) much above the permissible limit. Groundwater table in the capital dropped to 46.24 meters below the surface marking a steep fall of 20 meters in six years till 2003 as the water level in the rivers around it are declining fast.

Water Table Depletion in Dhaka

- One report showed that between December 2 and December 31, 2002, groundwater table fell by 0.34 metre or about one foot. It was 46.24 metres below the surface in 2003. The water table in Dhaka was on an average 42 metres below the surface in 2002, 37.78 metres in 2001, 34.18 metres in 2000, 31.86 metres in 1999, 30.45 metres in 1998 and 28.15 metres in 1997 and 26.6 metres in 1996. [Source: SOS-arsenic.net]

- Groundwater to the tune of 100 ML/Day has been abstracted in Dhaka during 2009.

Hydrological Impact (cont)

- Most alarming is that the lifted water is not being proportionately compensated by regular seasonal rainfall. On average 30% of lifted water is recharged in this area by rainfall.

- The maximum gaps may cause natural disaster at any time if the situation continues as cautioned by the experts. [source: sos-arsenic.net].

- With the backdrop of above situation, dewatering of pure drinking, arsenic free & irrigable groundwater to the tune of 800 ML/day by AEC over 38-years is not justified & not realistic. Moreover AEC’s figures of lifting groundwater not convincing in the light of existence of major fault in the centre of the basin.

- Over extraction of huge groundwater will damage the most potential and massive aquifer.

- AEC does not have concrete plan for water re-injection. They have future proposals for re-injection. However, their proposals of re-injection of 25% toxic & contaminated water will further jeopardize the situation.

- Open-pit mining operations involve lowering of the groundwater level which will ultimately generate acid mine drainage (AMD). Because of large discharge area, an innovative in-situ technology can be used to reduce AMD.

- Such a technology has been developed on a laboratory scale in Germany and is currently being tested in an aquifer already contaminated by AMD in a bid to assess and improve the ground water quality.

- We are not aware of any such plan by AEC.

- In order to save groundwater environment, water environmentalists advise to avoid groundwater extraction and search for surface water. Relying on groundwater extraction alone poses a grave threat to land subsidence. Land subsidence of a few inches took place every year in Bangkok and Mexico due to unbridled groundwater extraction two decades ago. Prof. Nazrul Islam of Dhaka University says WASA should avoid ground water extraction and search for surface water to save the ground water environment. Dhaka WASA is now looking for surface water.

- Over extraction of groundwater creates large vacuum within underground level due to lack of water recharge, on an average which is 30% in Bangladesh, making the situation very vulnerable to earthquakes.

- [Source: SOS-arsenic.net]

- Extraction of huge quantity of groundwater at Phulbari will put the north-western region of Bangladesh to the threat of natural disaster, land subsidence, land sliding and earthquake.

Geological & Mining Impact

- The overburden of Phulbari coal deposit is incompetent, unconsolidated and waterlogged. Installation of heavy equipments at intermediate depth and movement of large vehicles (200-tonne loaders) through the haul roads constructed in the benches over such a weak bed will be extremely difficult. The situation will be worsen during heavy monsoon period.

- Stability of the working bench will be in question at such weak bed. Maintenance of slope and slope angle will be very difficult.

- The coal extraction will be started from a depth of 200-250 meters. The coal will be transported to surface through haul roads made in the benches. The haul roads are to be concreted to facilitate movements of heavy vehicles. Thus the aquifer over the coal bed will be totally destroyed.

- AEC will remove & preserve top soil once mining operation begins in a particular block. This top soil will be preserved before it is brought back and spread on the top of the area filled. The top soil will be utilized after mining of one particular block which may take 4-5 years. It is very difficult to preserve top soil (20-30cm thick) for such a long time. The top soil will be washed away during rainy season.

- Before reaching coal floor to extract coal, the already lifted overburden materials will have to be dumped over large areas. During heavy monsoon these materials will spread beyond the mining area, escape through rivers and distributaries and clog the river system up to the Bay of Bengal. This will make environmental and ecological havoc. AEC has not addressed the issues precisely.

- During heavy monsoon in the Phulbari area, open-pit mining will be very difficult. Mining operation will have to be kept suspended for 2-3 months in a year during monsoon. At that time continuous pumping of water will be required to keep the mining area dry. Thus uninterrupted supply of coal to power plant will not be possible.

- 2-3 months storage facilities of coal at the surface will also be not possible.

- Existence of major faults in the Phulbari coal basin indicates presence of highly disturbed zone. This will facilitate rapid drawdown of water table. This will destabilize of major aquifer in the region. (AEC’s figures on water table drawdown not convincing in terms of Phulbari aquifer characteristics and Barapukuria experiences).

- Coal seam lies below more than 200 meters from the surface. Open-Pit coal mining should not be done below 150-200 meters. This is standard practice all over the world, specially in China and India.

- BHP-Australia left because they did not find coal within 150 meter depth. BHP develop & operates mainly open-pit mines in USA & Australia. They were looking for coal at a shallower depth for open-pit mining. BHP realized that open-pit mining at Phulbari at a depth of between 250 to 300 meters is not feasible.

- Wardell Armstrong (WA) estimated lifting of around 10,000 liters of water/sec from Barapukuria Coal Mine for open-pit mining. Since lifting of 10,000 liters/sec will damage the aquifer above coal bed, WA opted for UG mining at Barapukuria coal mine.

- Present recovery of 7-8% of coal from BCMCL UG mine cannot be the basis for open-pit mining at Phulbari. 40-50% recovery at BCMCL can be made by adopting appropriate technology.

- Asia Energy & German RWE experts advocate to apply RWE open-pit experiences at Phulbari.

- But RWE (German) open-pit mine and Phulbari (BD) open-pit mine is not comparable because of different geological, hydrological, social environment of the two coal basins.

Social Impact

- There are agricultural lands, villages, townships, forests, mosques, graveyards at the surface of Phulbari coal basin. The area is a thickly populated area. There are no barren and unused lands nearby. The people are dependant on their agricultural land. Rehabilitation and relocation of Phulbari people with proper compensation for their livelihoods will be a very difficult task.

- AEC forwarded Draft Special Legislation to GOB for land acquisition. It means AEC’s proposal does not cover under existing Bangladesh Land Acquisition & Requisition Act (Amendment) 1994.

- AEC proposes to acquire and compensate for the land using Govt. approved process. AEC’s proposal vis-à-vis Govt. approved process on this case need to be elaborated by AEC.

- AEC’s proposal to rehabilitate the people phase by phase and block by block in the refilled area will not be possible due to:

- Coal Mine Regulations will not allow affected people to live such close to a operative mine.

- Fertility of the refilled land will not be there for agricultural use.

- This proposal of AEC is not realistic.

Environmental Impact Assessment (EIA)

- Evaluation of EIA of Open-Pit Mining Project by DOE is very difficult due to following:

- There is no Coal Environmental Policy in Bangladesh.

- DOE is not equipped with relevant manpower.

- There was no chance to carry out the stringent “environmental impact studies” by AEC

German (RWE) & Bangladesh (Phulbari) Open-Pit Mine Not Comparable

- Asia Energy’s & RWE experts plead to use German Hambach Open-Pit Mines (RWE) experience to Phulbari Open-Pit Mines. But these two coal basins are different.

- Different grades of coal. Low grade coal (lignite) of RWE & high grade coal (bituminous) of Phulbari.

- RWE density of population 290-529/sq.km. Phulbari-916/sq.km.

- Phulbari people dependent on their land, RWE people are not.

- RWE rehabilitated 30,000 people in 50- years in barren & unused land, Phulbari to rehabilitate 2,00,000 in 30-years in usable land.

- RWE re-injected 100% pumped out water, Phulbari proposed to re-inject 25% water.

- Phulbari coal basin lies beneath a mega, massive, unconfined aquifer. RWE lies beneath a confined, small aquifer.

- RWE basin has few faults of 15m displacement, Phulbari has two giant faults of 150m displacement.

- RWE assessed & improved groundwater quality contaminated by AMD, AEC does not have any such plan at Phulbari.

- Diversions of road, rail, river will be in Phulbari. These diversions are not there in RWE.

- RWE mines developed by local experts, Phulbari mines are to develop by foreign experts.

- RWE mines clouser/abandonment are the responsibility of the original mine developer. In case of Phulbari, it is uncertain.

Open-Pit Versus Underground

- To generate 1000MW power from coal based power station, as proposed by AEC, – a maximum of 5.0 million tons of coal is to be produced annually which is very much possible by adopting underground mining method.

- Mine area of 1.00 sq.km. is reqd for UG mining whereas AEC proposed for mining area of 51.92 sq.km. for open-pit mining.

- About 5000 people need to be relocated for UG mining while 2,00,000 people are to be relocated for open-pit.

- Groundwater to the tune of about 8.00 ML liters/day to be lifted for UG mining while AEC proposes to lift 800 ML liters/day for open-pit.

- 100% discharged water from UG mining may be re-injected, thus arresting water level drawdown. AEC proposes 25% re-injection of discharged water.

- UG mining will not disturb the overlaying aquifer. Open-pit mining will damage the aquifer.

- Road, Rail, River needs to be diverted for open-pit mining. It’s not required for under-ground mining.

Underground Mining-best option

Exploitation of Phulbari coal is a must for Bangladesh. Specially to meet the power demand of the country – in the wake of gas crisis – development of Phulbari coal adopting underground mining method should be immediately undertaken. AEC’s requirement to install 1000 MW coal based power station can be made from Phulbari Coal Mine by underground mining method.

RECOMMENDATIONS

- GOB may undertake detail hydro- geological study on major & potential aquifer in the north-western region of Bangladesh in the light of AEC’s proposal for open-pit coal mining.

- GOB may advise AEC to submit under-ground coal mining proposal also.

- Water Management in Phulbari region is very delicate & crucial for open-pit mining. AEC must address the issue in detail.

- AEC to restore original water table by land reclamation & sand stowing after closure of open-pit to accelerate recharge of ground water system of the area.

- Remedial measures to solve the problem of ground water depletion should be undertaken by AEC augmenting water level by implementing artificial recharge system such as Rain water harvesting, Creation of water lagoon in mined out region and recharge through abandoned tube wells, if AEC’s open-pit mine proposal is approved by GOB.

- A Ground Water Task Force, formed by Govt. and headed by Mr. S.K.M. Abdullah, former DG, GSB & Chairman Petrobangla, recommended to formulate Groundwater Act & Ground Water Commission in July 2002 for all ground water management & activities. Govt. may look into these matters.

- Bangladesh Coal Environmental Policy is to be formulated by the Govt.

- Having hydro geological study of the NW aquifer by GOB, open-pit & under-ground mining proposal from AEC – Govt. may take decision over exploitation of Phulbari coal which is vital for the interest of Bangladesh.