Chapter 40A

Engr. Abul KM Shamsuddin, IIFC Bangladesh Mining Consultant, Presented “Production Improvement from Central Zone of Barapukuria Coal Mine Adopting Stowing Technology” in a Workshop on Coal Sector Development Strategy at Hydrocarbon Unit Conference Room, Dhaka on September 06, 2012.

-Engr. Abul K. M. Shamsuddin

Bangladesh Mining Consultant,

Infrastructure Investment Facilitation Company (IIFC),

& PricewaterCoopers India Ltd (PwC).

Venue: Hydrocarbon Unit Conference Room

Dhaka, September 6, 2012.

Production Improvement from Central Zone of Barapukuria Coal Mine Adopting Stowing Technology

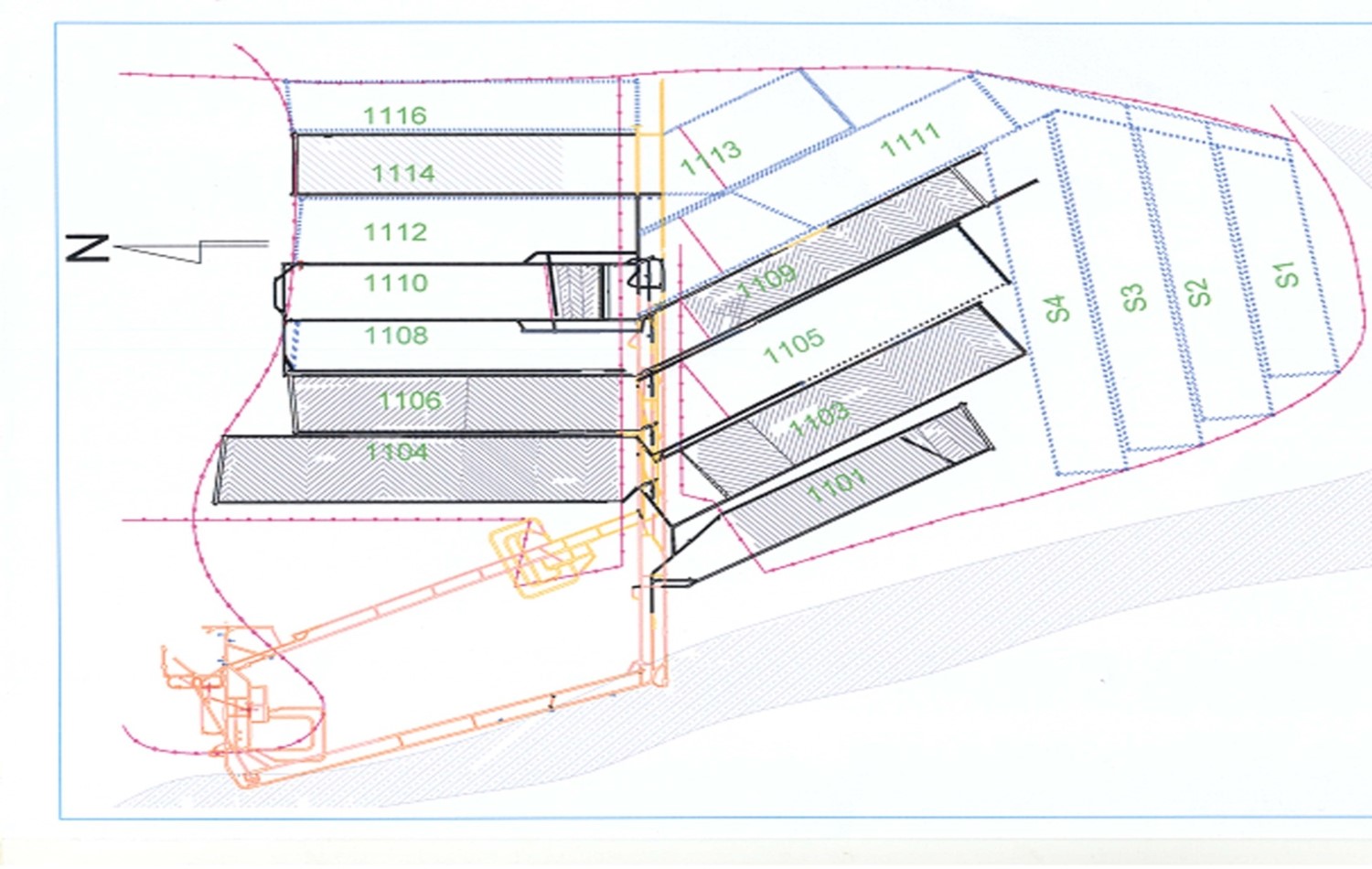

- Presently VI seam (average thickness 36m) is being worked in the central part of Barapukuria Coal Mine by multi-slice longwall mining with caving.

- The first slice of 3m height has already been extracted and the second slice of 6m height is proposed to be extracted below the first slice goaf by Longwall Top Coal Caving (LTCC) Method.

- In the absence of scientific studies, uncertainties exist regarding behavior of strata, support density required, ingress of water, etc. in the second and subsequent slices.

- To ensure safer and sustainable mining, working seam VI in ascending order with stowing starting from bottom of the seam is suggested.

- Hydraulic sand stowing has been successfully used in many countries for extraction of thick seams.

- Adoption of stowing in Barapukuria Mine will help reduction in strata control problems.

- It will help in reducing the risk of spontaneous combustion.

- Stowing will help improvement in face ventilation as longwall mining with panel barriers can be practiced.

- It will reduce in make of water from aquifer due to reduction in ground movement.

- Mining in ascending order with stowing will prevent further damage of the upper seams.

- For safety of miners and for conservation of coal under Barapukuria environment, adoption of Stowing Technology is essential.

Constraints to Overcome for Adoption of Stowing

- Sand to transport to mine from Jamuna river located at a distance of 50-60 km.

- Powered Supports to be specially designed to accommodate stowing pipes and to have rear support extensions, etc.

- Production process will slow down due to extra-shift time consumed for stowing operation.

- Additional capital investment required to transport sand from river.

- Additional operating cost for stowing operation.

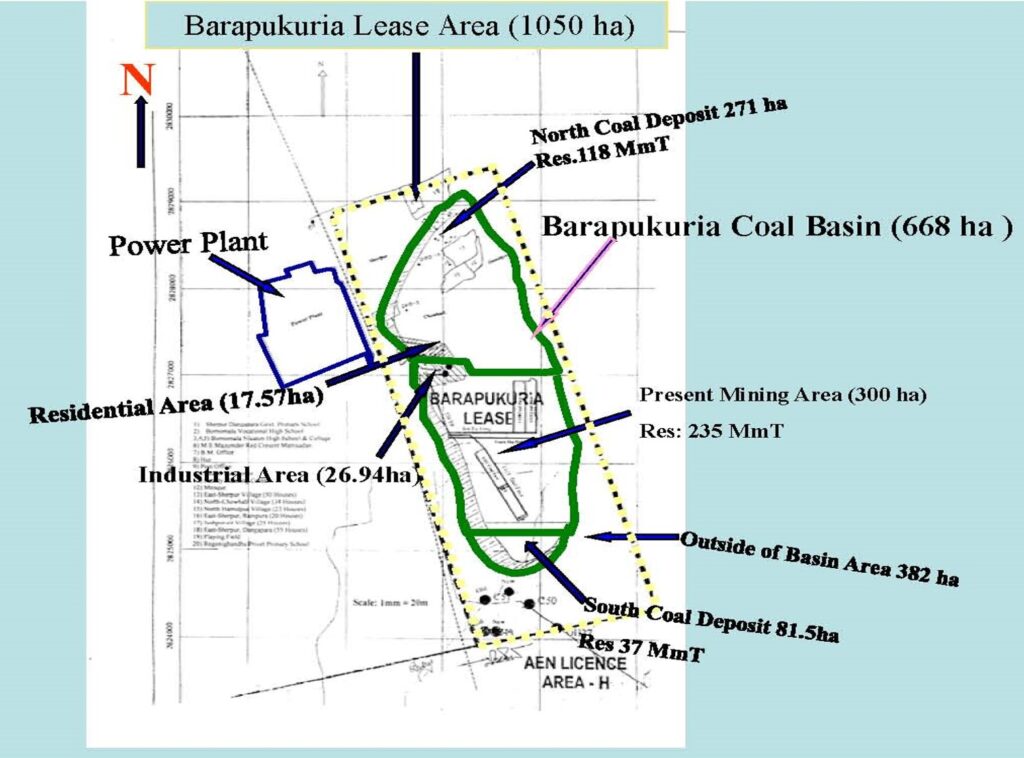

- Present mining area where XMC-CMC is now working

Central Part = 300 hectare = 3.00 sq km: Reserve = 218 million tons.

No.1 = Southern district; Area = 2.2 sq km.

No.2 = Northern district; Area = 1.4 sq km.

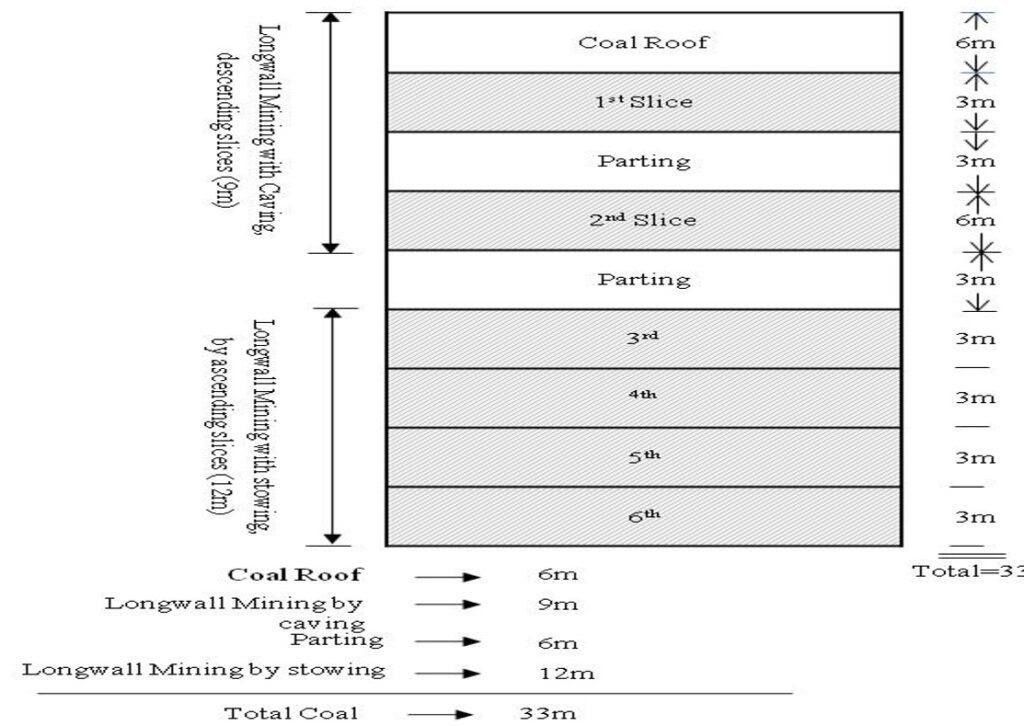

Slice Mining with Stowing has been shown in the diagram in next slide.

Longwall Slice Mining by Stowing

- After completion of extraction of 2nd slice by LTCC method, it is recommended to adopt multi-slice longwall mining with stowing in ascending order.

- In total, 5-slices of 3m thick will be taken from the bottom of the seam-VI, in the central part of Barapukuria Coal Mine, as shown in the former slide.

- From the 5-slices, 25.00 million tons of coal may be produced within 25-years.

- Stowing materials may be transported from Jamuna River located at a distance of 50-60 km from Barapukuria coal mine.

- BCMCL may explore the possibility of sand-mining from Jamuna bank for making long time availability of stowing materials.

- Due to the problem of fire, strata control, water inflow in the mine, there are some uncertainties regarding sustainability of Mining at Barapukuria.

- Therefore, slice mining in ascending order with stowing may be planned at this stage when 2nd slice mining adopting LTCC is going on by BCMCL.

- In other words, a feasibility study regarding application of Stowing is to be carried out by BCMCL during 2nd slice mining.

- For the safety and sustainability of Mining VI-seam of Barapukuria Coal Mine,

- For the conservation of Coal,

- To reduce the risk of spontaneous combustion, the problems of strata control, reducing ground movement, minimizing water inflow from aquifer,

- To prevent further damaging of upper seams,

adaptation of Stowing Technology should be given serious considerations.

[End of the Presentation by Engr. Abul KM Shamsuddin].