Autobiography

Chapter 14

Engr. Abul KM Shamsuddin Visited & Worked in Miike Collieries & Taiheio Collieries in Japan during September-November 1989 under JICA Technical Assistance Program.

- Myself, Engr Abul KM Shamsuddin, visited Miike Collieries, during October 1989, the Oldest, Largest and Most Mechanized Coal Mine of Japan.

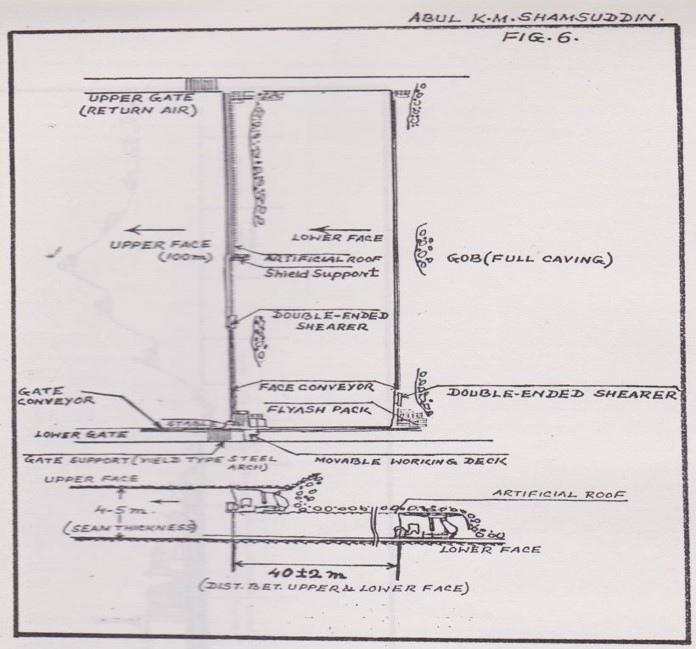

- Miike Coal Mine [Colliery] is located in the southern part of Fukuoka Prefecture in the Kyushu District of Japan. As the then General Manager, Mines and Minerals Directorate of Petrobangla, I have undertaken extensive visit and work in the Underground Coal Mine. The colliery was the largest and oldest in Japan and was considered as one of the most modern and efficient collieries in the world during 1989-1990. It was producing 5.0 million tons of clean coal annually with fully mechanized longwall faces adopting simultaneous slice mining in two slices (upper face & lower face) in a 5.0 meter thick coal seam (please see the diagram). In this system, a longwall face is set in the lower part of the same seam. The lower face is worked about 40.0 meters behind the upper face. The face layout has been shown in the diagram.

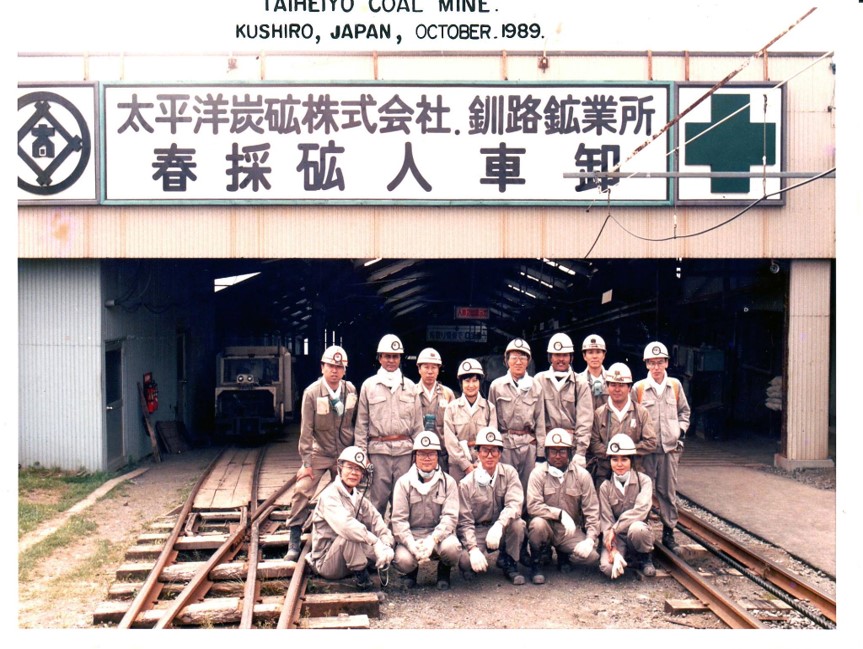

- The pictures also show visiting Taiheio Coal Mine in Kushiro district in the Hokkaido Island in the extreme north of Japan. The UG Mining in the Taiheio Coal Mine was going on at the mediterian sea-bottom about 1.0 km away from the sea-shore using mechanized longwall mining during the period of my visit. It was an awful experience of seeing the mining at deep-sea bottom, which tempted me to work in the mine face.

- My visit to Miike Colliery and Taiheio Colliery in Japan and having my experiences about working in simultaneous slice mining system helped me greatly in evaluating M/S Wardell Armstrong UK Ltd Feasibility Report on Techno-Economic Feasibility Study of Barapukuria Coal Deposit in 1991-1992.

- Also, my above experiences helped me in formulating mining method in the Techno-Economic Feasibility Study (TEFS) Report of Khalashpir Coal Deposit, Pirganj, Rangpur – A Concern of Hosaf Gr. of Companies – Dhaka in 2004-2006 as Project Director of Techno-Economic Feasibility Study (TEFS) Report of Khalashpir Coal Deposit.

Engr. Shamsuddin is in the front row 2nd from right & Sirajul Islam Chowdhury is in 2nd row 2nd from left.

Engr AKM Shamsuddin is sitting 1st from left.

Engr Abul KM Shamsuddin is sitting at extreme right.

Engr. AKM Shamsuddin is seen 3rd from left. Sirajul Islam Chowdhury is seen 1st from left.

Engr. AKM Shamsuddin is seen delivering farewell speech on behalf of the Participants.