Chapter 10

- Techno-Economic Feasibility Study [TEFS] of Khalashpir Coal Deposit; Pirganj Upazilla; District Rangpur; Bangladesh – [2004-2007].

2. Hosaf-Group (Bangladesh) & CMC (China) Joint-Venture Proposal (2016) to Govt. of Bangladesh for Construction & Development of Khalashpir Coal Deposit:

-Presented, in 2016, by:

-Engr. Abul KM Shamsuddin; Project Director,

–Techno-Economic Feasibility Study [TEFS] of Khalashpir Coal Deposit & Project Coordinator, Hosaf-China Joint Venture Consortium.

Khalashpir Coal Project: A Joint Venture of CMC & Hosaf

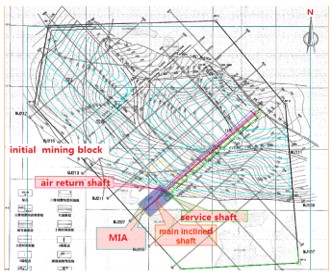

Resource & Location of Coal Deposit

- Bangladesh, a land of natural beauty, has a significant source of vast quantities of natural resources.

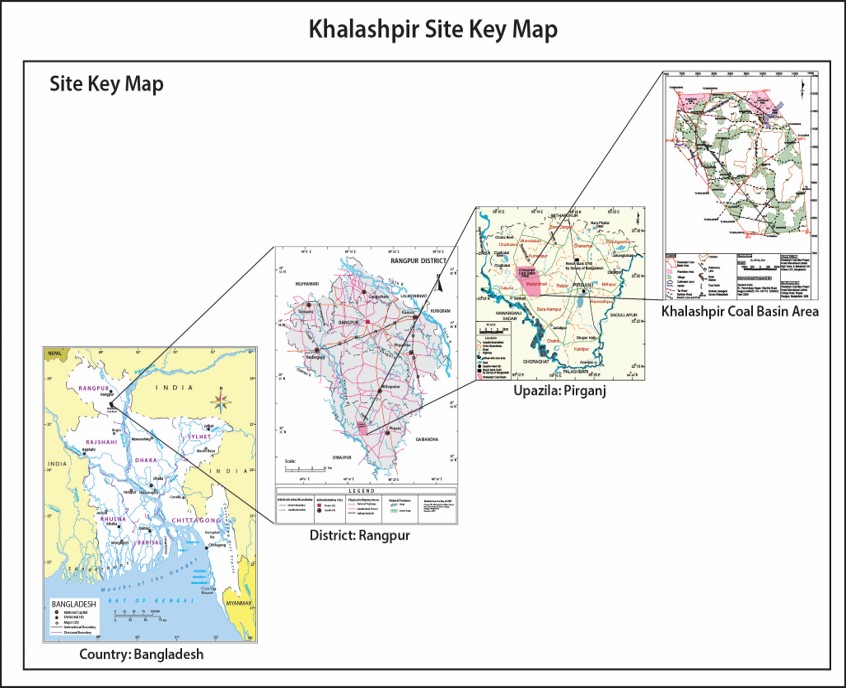

- Khalashpir is located in north-west of Bangladesh at Pirganj Upazila under Rangpur District, which is around 300 km north of Dhaka.

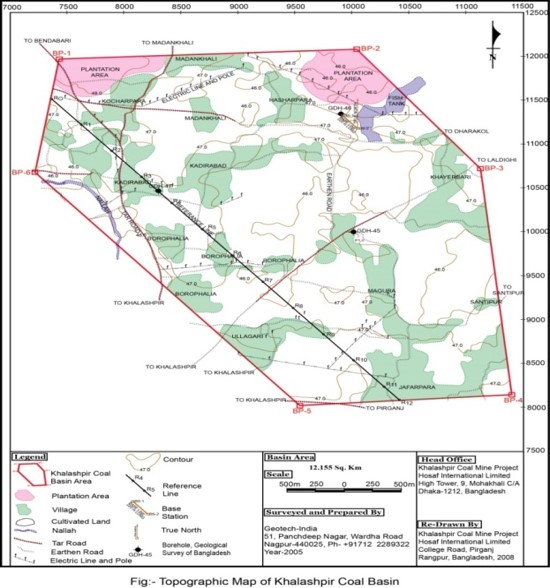

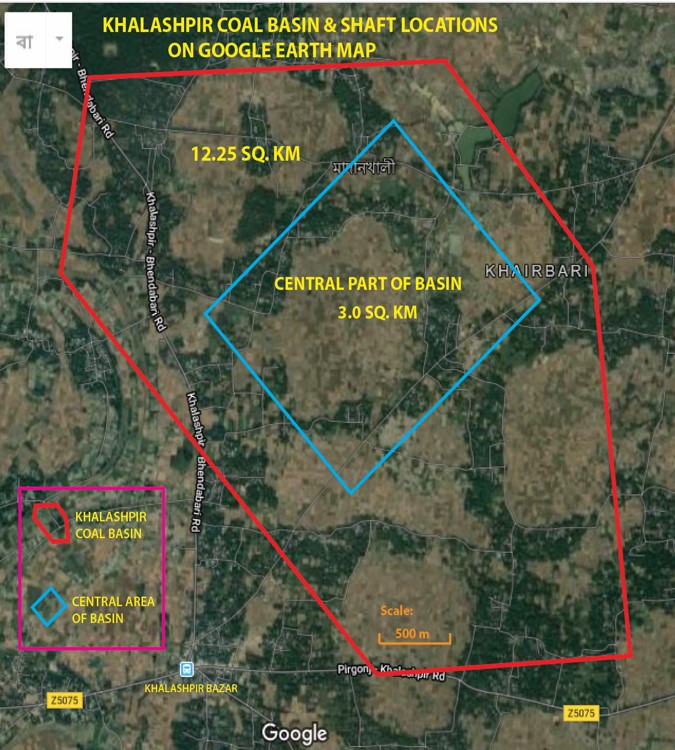

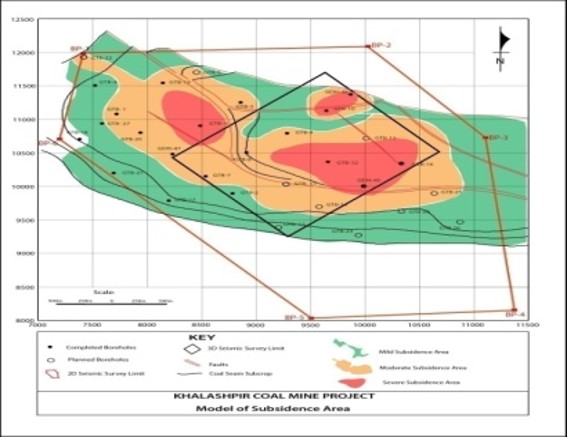

- Khalashpir Coal Basin, an area of 12.15 sq. km, is at a distance of 13 km towards west of Pirganj Upazilla with a coal deposit in 7.5 sq. km.

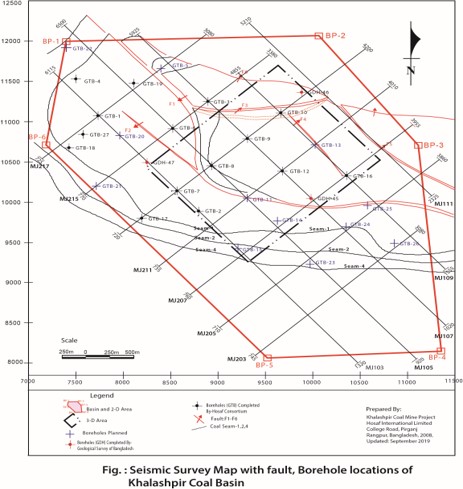

- In 2004, Hosaf Consortium was awarded the Exploration License and they undertook survey to evaluate the deposit through topographic survey, 2D & 3D seismic survey, and drilling of boreholes.

- 15 boreholes were drilled covering coal basin area of 12.25 sq. km during 2005-2006. All the holes penetrated coal seams.

- According to boreholes and seismic data total reserve of coal is 451 million tons.

Coal Seams

- During the course of drilling, eight (8) coal seams were encountered at depths ranging from about 240m to 480m.

- Initially Seam 1, 2 & 4 has been considered for mining on geological settings.

- Proven coal reserves in Seam 1, 2 & 4 is 297.57 million tons.

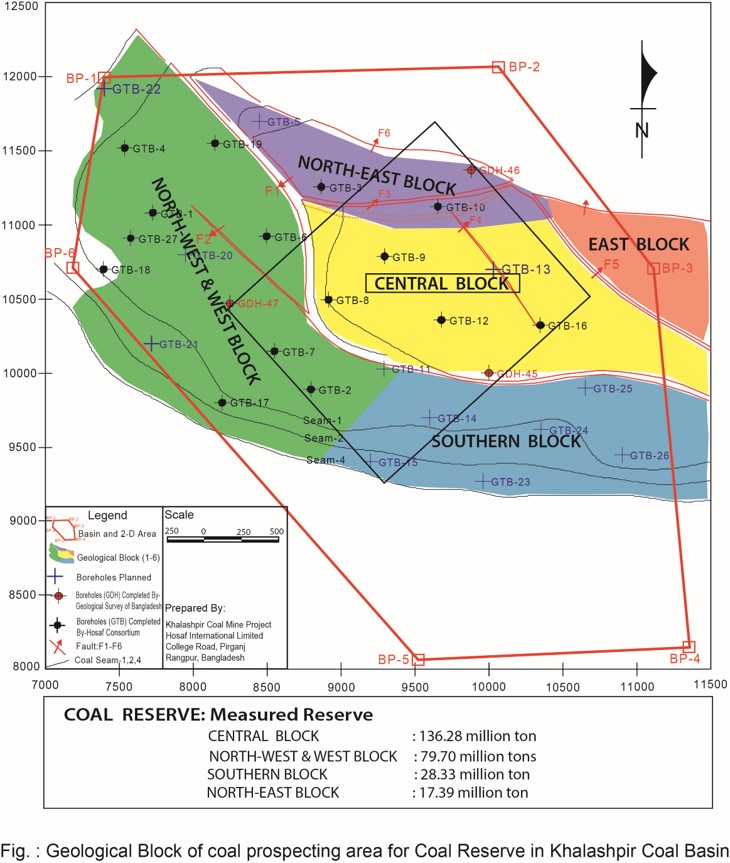

Coal Basin

Coal basin is divided into following blocks:

- Central Block

- South Block

- West & North-West Block

- North-East Block

- East Block

Measured Coal Reserve

Measured reserve in:

- Central block = 136.28 million tons

- East block = 40.00 million tons

- North-East block = 17.39 million tons

- West & North-West block = 79.70 million tons

- South block = 28.33 million tons

Project Development Schedule

A time frame to conduct seismic, drilling, geo-physical logging, chemical analysis of coal, hydro-geological investigation, geo-technical investigation, EIA & SIA of the Coal Mine is proposed as follows:

- 2D Seismic Survey = July 2021 – Dec 2021;

- Exploration drilling of 10 boreholes = Jan 2022 – June 2022. (Spacing between 2 holes = 250m);

- Geo-physical logging, chemical analysis, geo-technical investigation = July 2022 – Dec 2022.

- Hydro-geological test/pump test, EIA & SIA = Jan 2023 – June 2023;

- Mine Construction & Development = January 2023 – December 2025 (3-years);

- Bye Product from Shaft & Roadway = 0.80 million tons from December 2025.

- Commencement of Production 1.00 million tons = January 2026. (Generation of 600 Mw of Electricity from 6th year).

- Generation of 1200 MW of Electricity from 12th Year.

Central Basin

- First phase of mining will be in the Central basin area.

- The area of central block is 3.0 sq. km and measured reserve is 136.28 million tons of seam-1, 2 & 4.

- In the first phase of mining, about 100 million tons coal will be extracted over 20 years, where mine construction period will be 3 years.

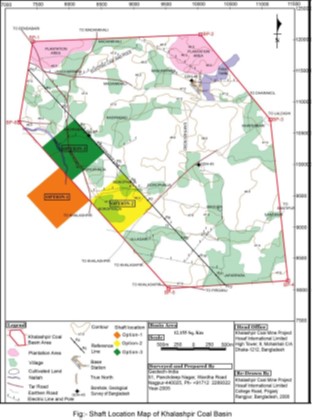

Shaft Location & Sinking

- Three shaft locations have been proposed at the southern-western boundary as Option-1, Option-2 & Option-3. The size of each shaft locations including surface facilities area is 1.0 sq.km.

- Option-1 is selected for surface facilities and

- 2 shafts – i.e. cage shaft for men and machinery & skip shaft for coal.

- There will also be provision of 3rd shaft/ventilation shaft as per requirement of coal production and other facilities.

- Ground freezing method will be applied for shaft sinking in Khalashpir.

Mine Plan & Design

Following will be built at the surface:

- Mine office

- Workshop

- Store-yard

- Lamp room

- Water treatment plant

- Coal washery plant

- Generator house and

- Mine rescue station

Coal Extraction

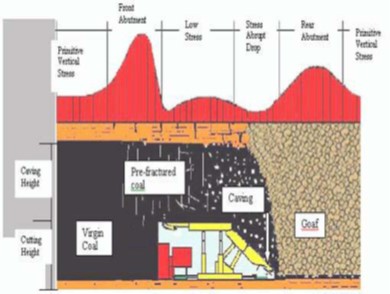

- Long-wall Top Coal Caving method will be applied with Long-wall Top Mining with caving/stowing, room and pillar mining where necessary.

- Expected coal recovery will be 60% -70% and production from blocks is adjustable as per market demand.

Coal Quality

- Khalashpir coal is high grade bituminous coal having coking properties at some layers of the seam. It contains –

- Moisture: 2.14%

- Ash: 13.30%

- Volatile Matter: 26.72%

- Fixed Carbon: 59.97%

- Sulfur: 0.67%

- Calorific Value: 12,415 BTU/lb

Coal Production

Total Production from Central Block in 20 years = 100.80 million tons

This is about 70% of the measured reserve in seam-1, 2, & 4

No production in first 3 years : Development period

- Year 1 (2023)

- Year 2 (2024)

- Year 3 (2025)

- Year 4 (2026): Final stage development ; Partial Prod: 0.8 MT

- Year 5 (2027): 1.00 million tons

- Year 6(2028): 3.00 million tons: 600 MWH Power Generation

- Year 7 (2029): 3.00 million ton

- Year 8, 9, 10 (2030-32): 15.00 million ton: 1200 MWH Power Generation from 8th Year & continue till 20th year i.e. upto 2042.

- Year 11 (2033): 8.00 million tons

- Year-12 to Year-20: 70.00 million tons in 9-years by 2042.

Commercial Use of Coal

- Power Stations for power generation:

Around 60% to 70% of the produced coal from Khalashpir Coal Mine will be used for power Station.

- Two super-critical Power Units of 600 MW each:

Khalashpir coal will be able to generate total 1200 MW of electricity during the mining period.

- Job opportunities:

Through two big industries – Coal Mine & Power Plant

- For other local coal based industry:

Coal may also be made available to other local coal based power plants thereby contributing in reducing the foreign funds required to import coal.

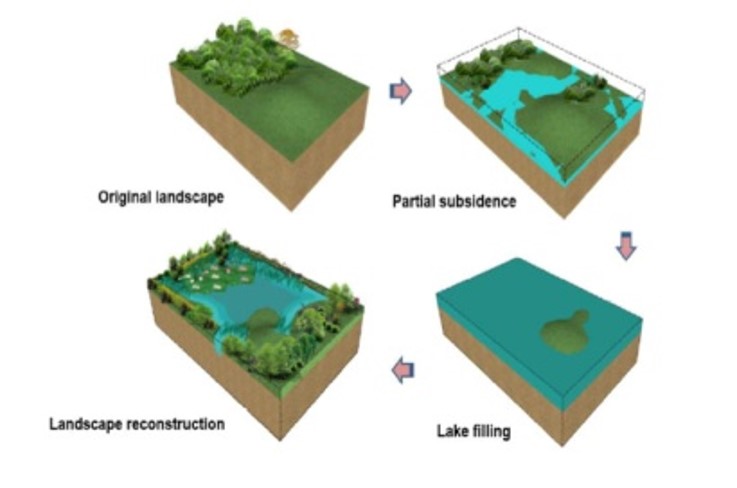

Subsidence Effect

Expected Subsidence area = 3.0 sq. km

- 1st five years – No subsidence

- 2nd five years – 3m

- 3rd five years – 2m

- 4th five years – 3m of subsidence

Total Subsidence depth = about 8m (26.24 ft) in the entire mining life.

Measures for Subsidence

Measures to be adopted by Crop Compensation:

- 1st five years – Continue cropping of the agricultural land.

- 2nd five years – The compensation of crops will compensate 1.5 times of grows, and resettle of households in resettlement area, besides these 1-3 member of each household will be employed.

- 3rd five years – Different SME projects will demonstrate in the affected households.

- 4th five years – Fish farming and ecological rehabilitation

Measures to be adopted to reclaim/protect subsidence of land :

- Fish farming: By applying Deeper and Pad shallow method, and will be applied modern fish farming.

- Ecological rehabilitation: Restore ecological environment by making banks, plantation of trees and grass.

Rehabilitation

Out of Total Central Block Area: 3.0 sq.km

- Agricultural Land area is 2.41 sq.km &

- Village area is 0.59 sq.km

For Agricultural Land

- This area will be acquired from the landowner.

- Landowners will also be rehabilitated with houses in the resettlement area

Village Area contains 603 Houses and

- Total 3007 inhabitants/dwellers

- Inhabitant/dwellers of the area will be rehabilitated at the proposed resettlement area of about 150 acres of land. Location: Vill. Boalmari, Mouza. Bisna, JL.No.19, Union. 6 no. Tukuria, P.S. Pirganj, Dist. Rangpur.

- The resettlement area will be facilitated by constructing houses, schools, mosque, primary health care facilities, playground, park, plantation area with other modern facilities.

Conclusion

- Techno-Economic Feasibility Study of Khalashpir Coal Deposit submitted to Bureau of Mineral Development (BMD) on August 23, 2006 seeking mining lease for the development of the coal field.

- Financial analysis (B. C. Ratio and IRR) of the project shows that the project is technically feasible and economically viable.

- Khalashpir coal can generate 1200 MW of power from 12th year to 30th year.

- Clearance from the GOB is requested to go ahead with the project observing all the required formalities.

- Marching Ahead in the Energy Sector

- China National Machinery Import and Export Corporation (CMC) and Hosaf International Limited (A Sister Concern of Hosaf Group)

Development of Khalashpir Coal Mine under JV Programme on 26 Dec 2020 at Hosaf Office.

Site along with BMD Team on 6th June 2005 to see the overall progress of Feasibility Study work.