Autobiography

Chapter 2 Post-Graduate Degree in Mining Engineering

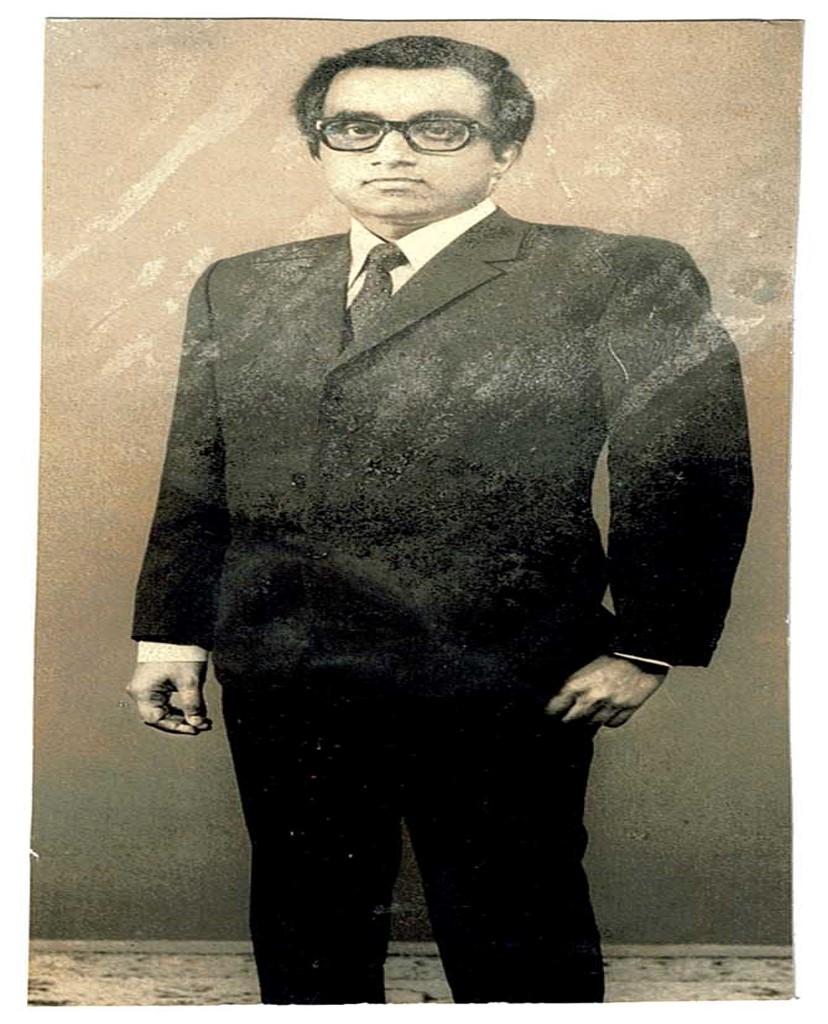

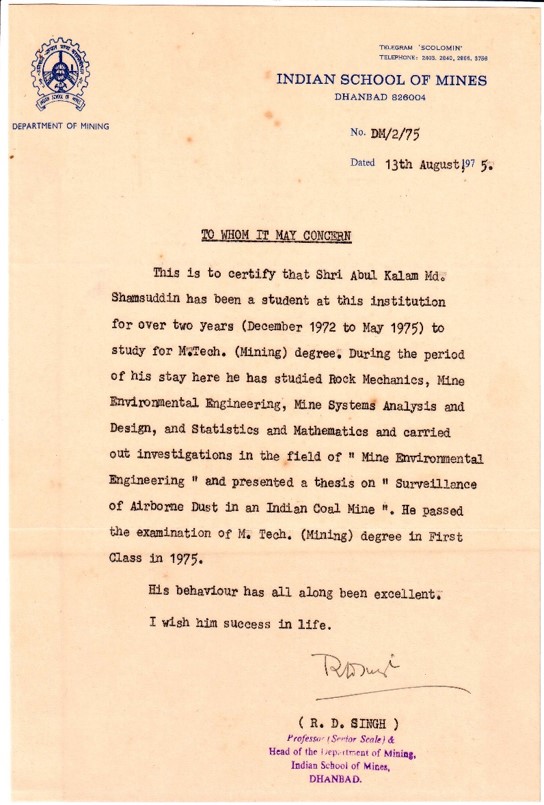

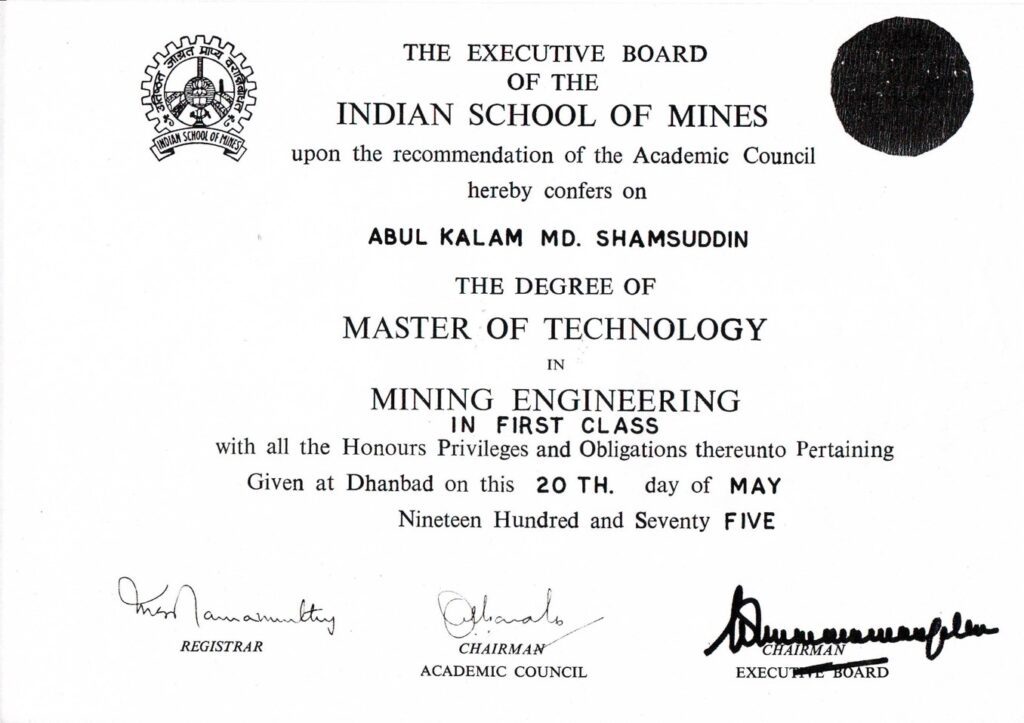

Chapter-2: Engr. Abul KM Shamsuddin obtained Post-Graduate Degree in Mining Engineering from Indian School of Mines (ISM), Dhanbad, India on August 1975 under Indian Govt. first scholarship to Bangladesh.

- First Govt. of Bangladesh nominated Engr. Abul K. M. Shamsuddin, a Graduate Mining Engineer of Bangladesh, hailing from Chittagong District for Post-Graduate Study in Mining Engineering in Indian School of Mines (ISM), Dhanbad, India in order to Develop Jamalganj Coal Fields in particular and Bangladesh Coal Fields in general.

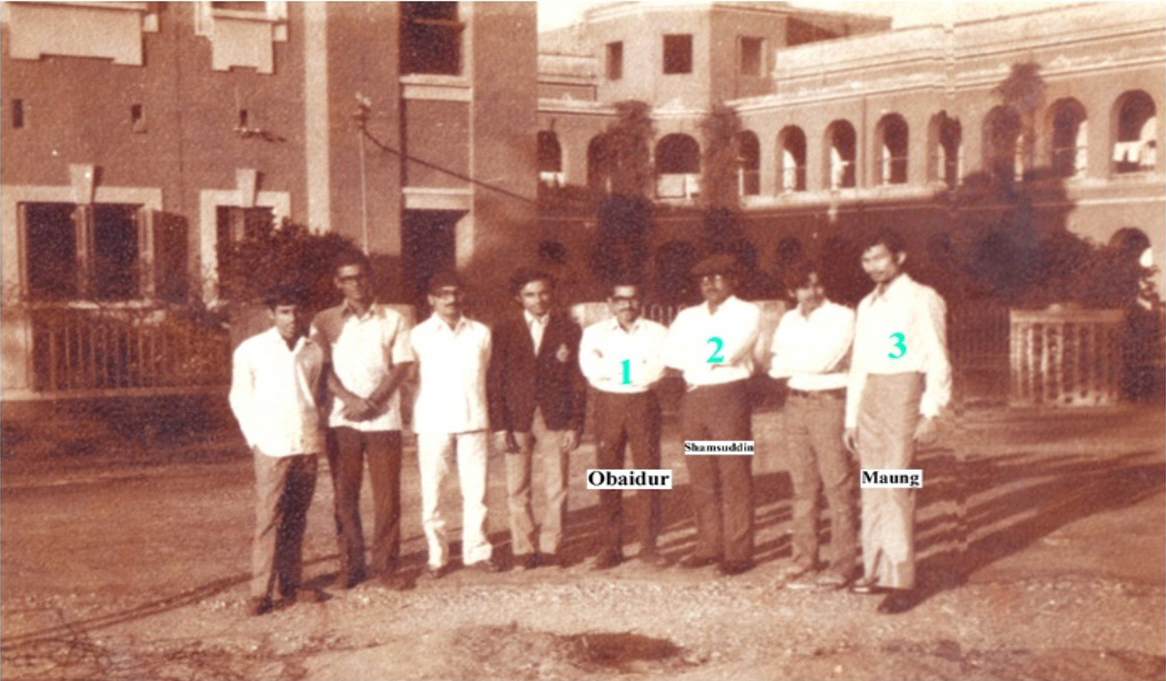

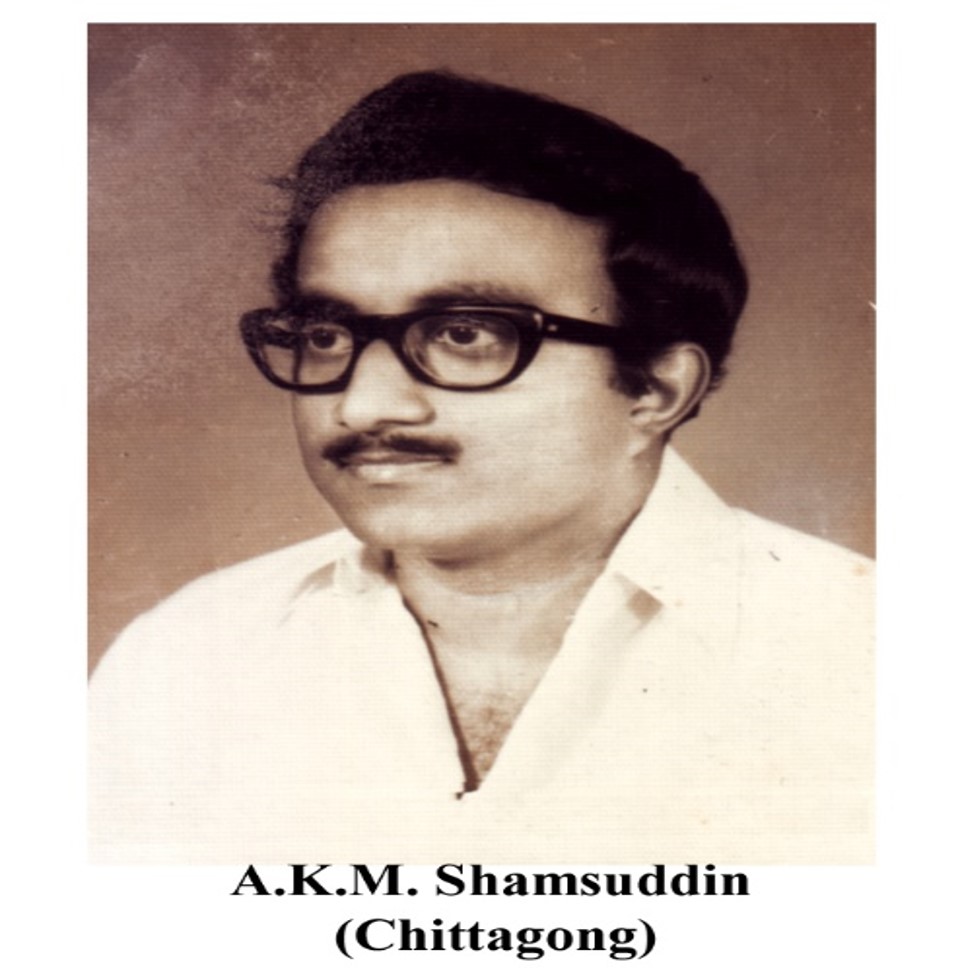

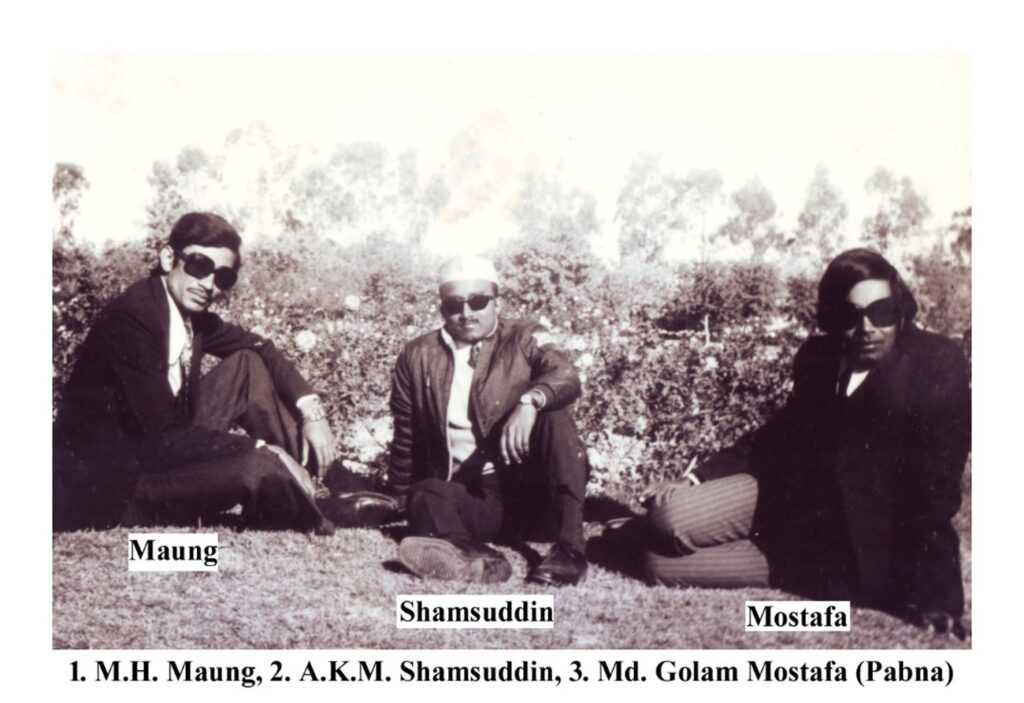

- Another 3-graduate mining engineers namely, Mr. Gholam Mostafa (from Pabna), Mr. Obaidur Rahim (from Faridpur), and Maung Haung Maung (from Chittagong Hill Tracts) were also nominated for Post-Graduate studies in Mining Engineering. The selection of four Bangladesh graduate mining engineers were made by Ministry of Education, Govt. of Bangladesh on competitive basis from the available Bangladeshi graduate mining engineers.

- Jamalganj Coal deposit was about 1054.00 million tons spreading over 8-seams at a depth ranging from 800 meters to 1150 meters. The feasibilities studies were made by M/S Fried Krupp of West Germany Firm in 1966 in a very detail manner and then M/S Powell Duffrin Technical Services of UK re-assessed the report of M/S Fried Krupp in 1969 & recommended to extract coal from Jamalganj deposit. Govt. of Bangladesh aimed to develop Jamalganj Coal Fields and for that reasons sent Graduate Mining Engineers for higher & specialized studies in Mining Engineering in India.

- The issues of nomination and selection of graduate mining engineers by the very first Govt. of Bangladesh, drawing from the district of Chittagong, Pabna, Faridpur and Chittagong Hill Tracts have been discussed elaborately in the next page.

- In December 1972, we, the 4-graduate Mining Engineers (Myself, Abul Kalam Md. Shamsuddin), (Md. Gholam Mostafa), (Md. Obaidur Rahim), and (Maung Haung Maung) were awarded Indian Govt. Scholarships under “Indo-Bangladesh Cultural Exchange Programme” for higher studies in Mining Engineering in Indian School of Mines. This was the first scholarship for Bangladesh Students arranged by FIRST SOVEREIGN & INDEPENDENT GOVT OF BANGLADESH.

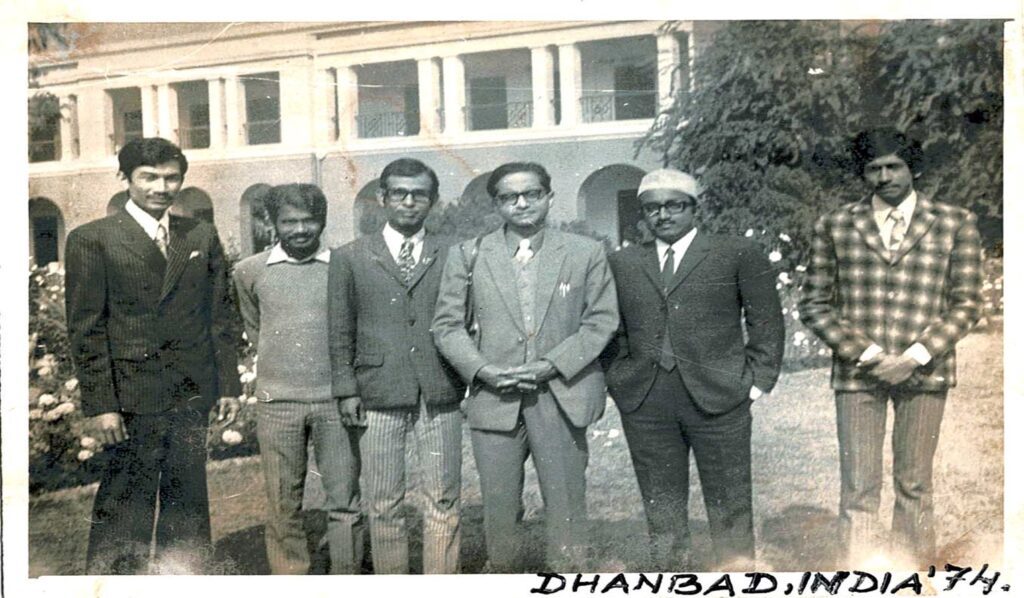

- We departed for India in December 1972. The First Secretary of Indian High Commission in Dhaka saw us off at Dhaka Tejgaon Airport. The Joint Secretary, Ministry of Education, Central Govt. of India, from Delhi, ceremonially welcome us, at Dumdum Airport in Calcutta in December 1972. Then from Hawra Railway Station, Calcutta we went to Dhanbad under Bihar State by Coal Field Express. The Students Union of Indian School of Mines (ISM) garlanded us, being the very first student batch from newly independent Bangladesh, in Dhanbad Railway Station and took us to School of Mines in a festive manner.

- Indian School of Mines (ISM) is a world renowned Mining Institute – which offers courses in Mining Engineering, Petroleum Engineering, Geology & Geophysics from graduate level to Ph.D. & D.Sc level. Our 2-years Post-Graduate Mining Engineering Course was Mining-Industry oriented. We worked & studied in various Indian Coal & Metal Mines spreaded throughout India and more specifically in Jharia Coal Belts under various Mining Engineering Disciplines. We also worked in Central Mine Planning & Design Institute (CMPDI), Ranchi; Central Mining Research Station (CMRS), Dhanbad, and in the Directorate Mine Safety, Dhanbad, India & also in the area of Mine Environment & Mine Hazard, etc.

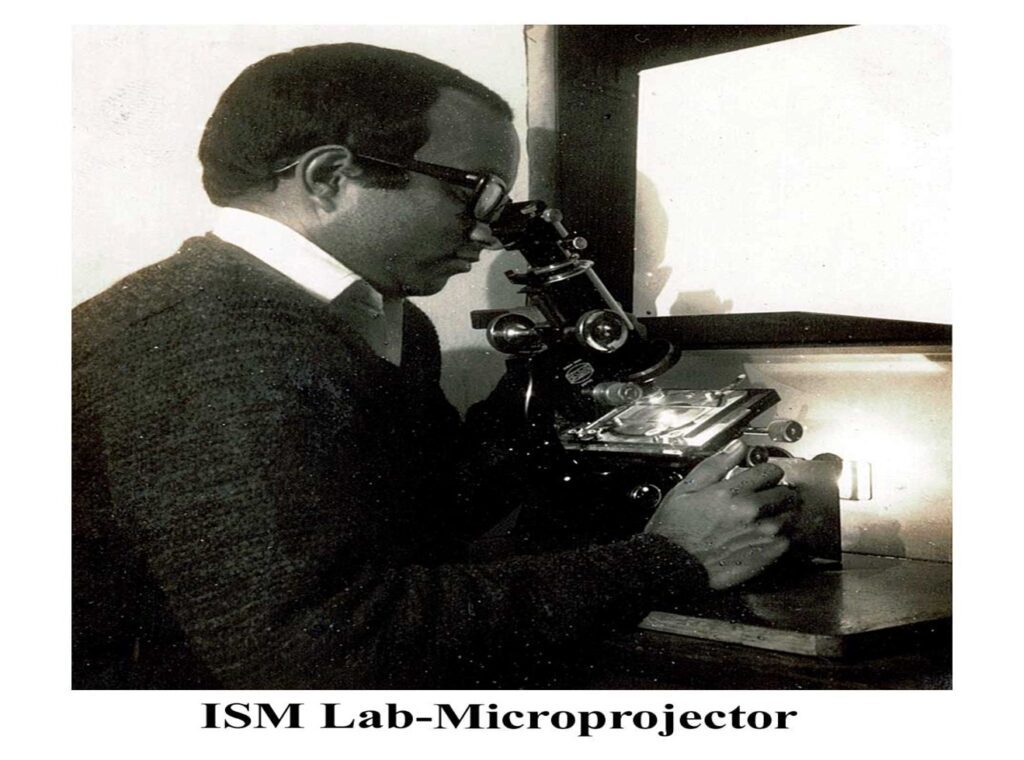

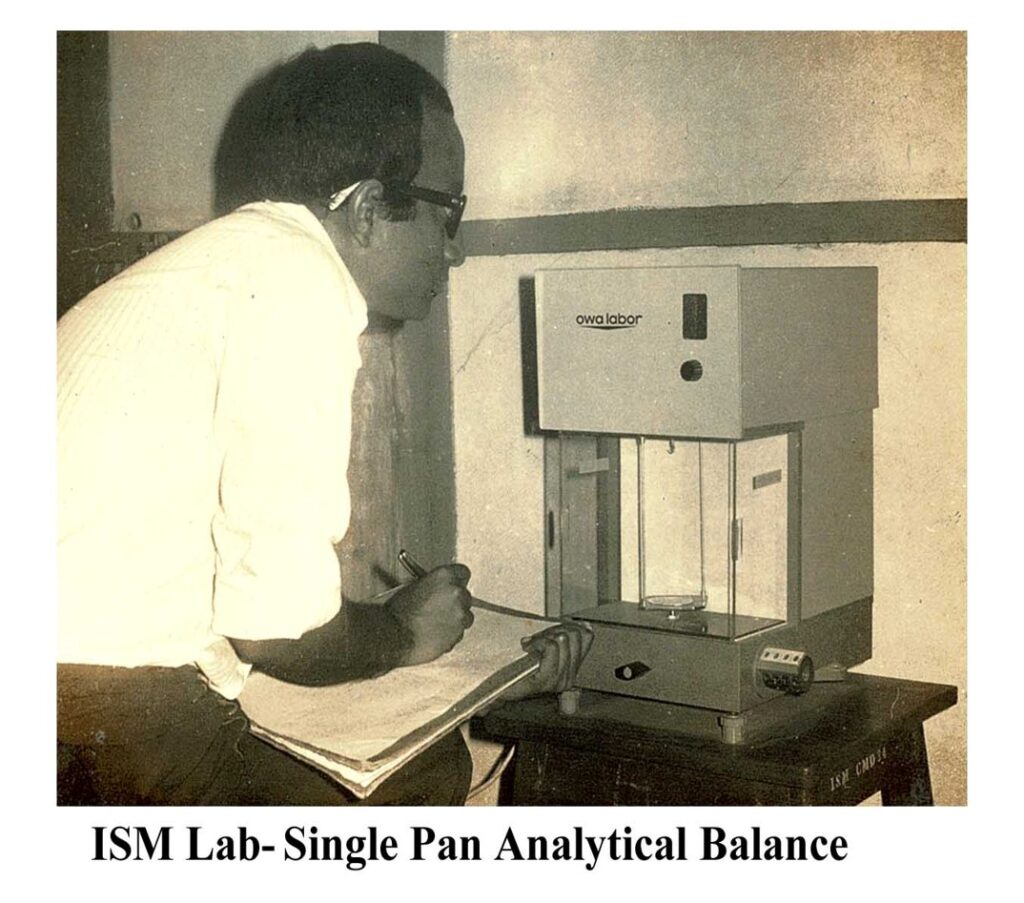

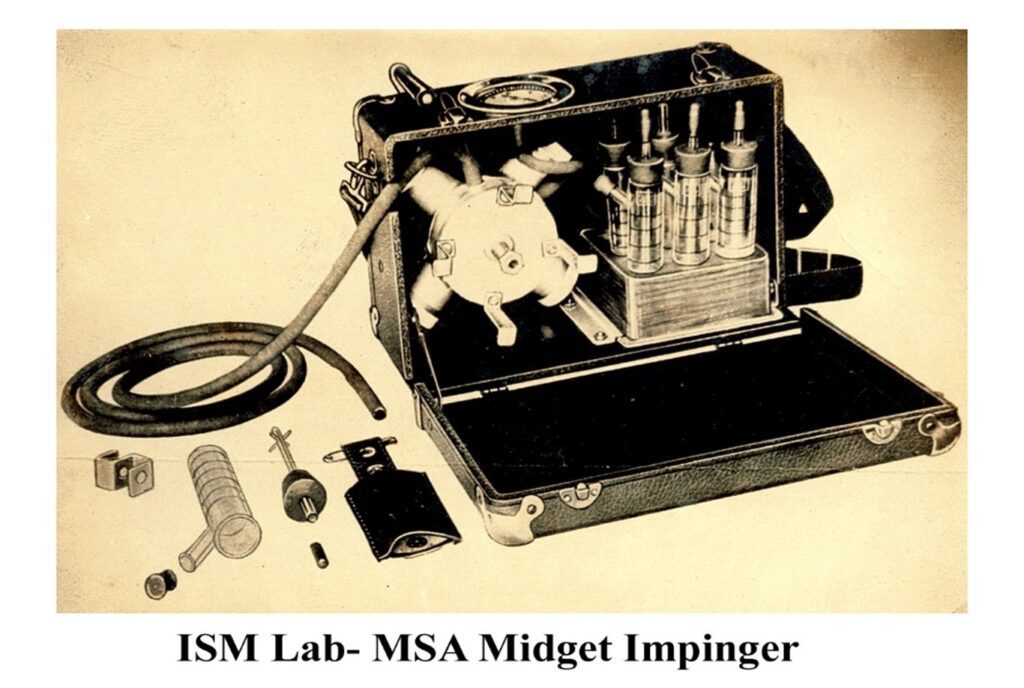

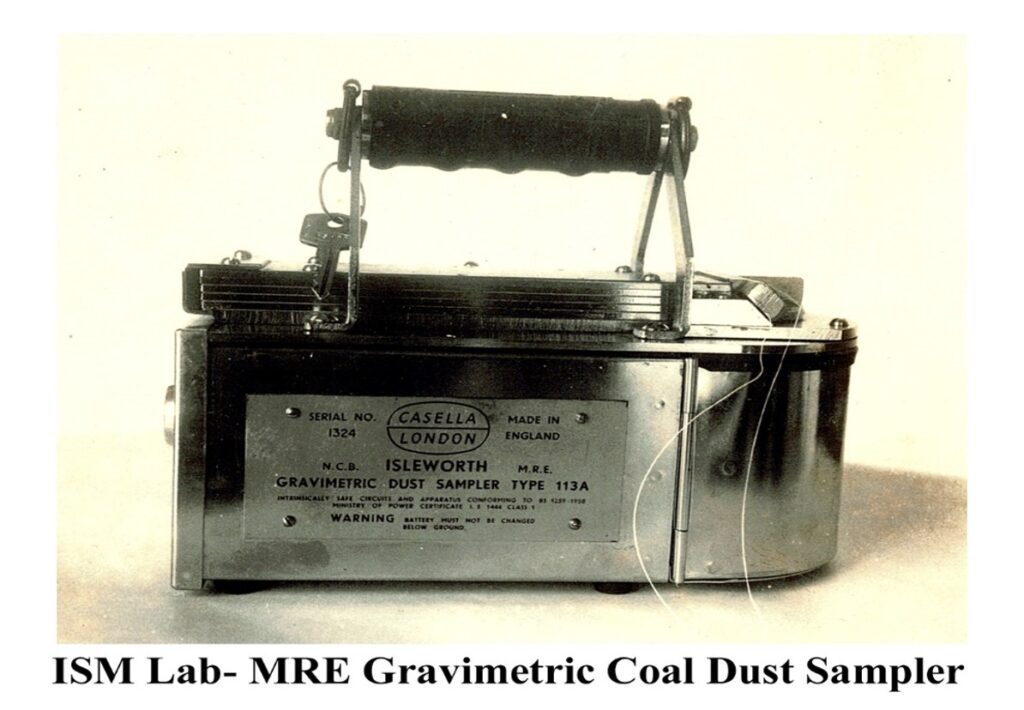

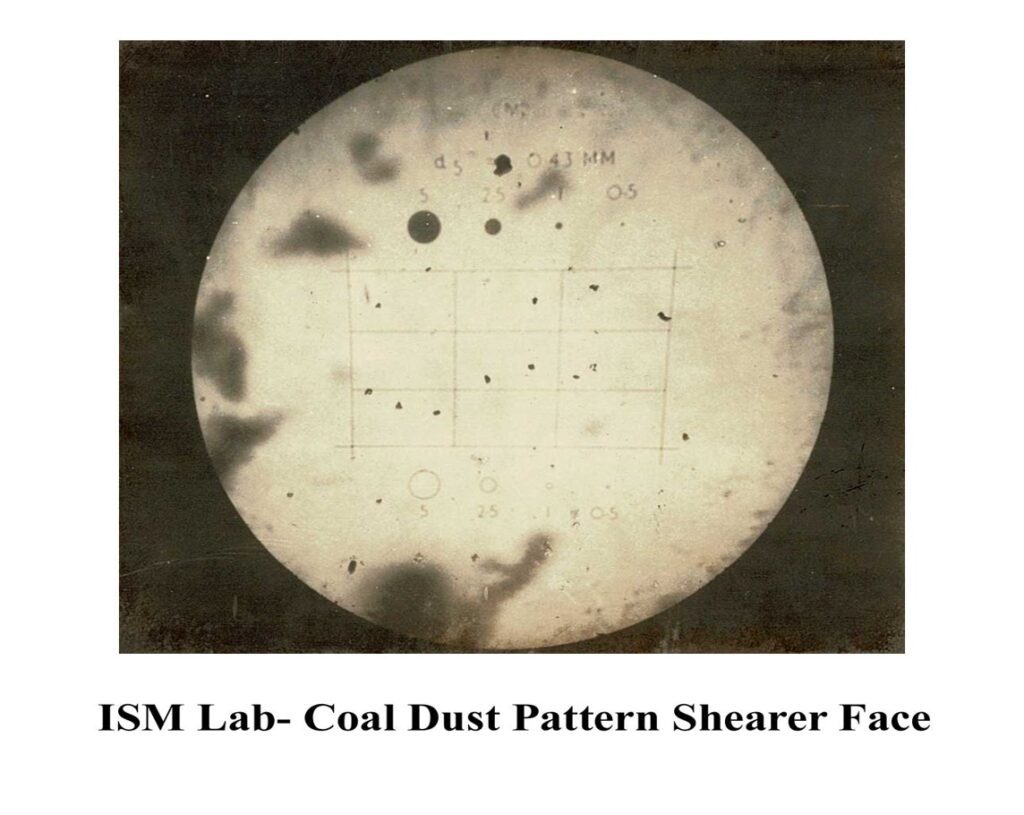

- As a part of my M. Tech programme, I carried out investigations & research on the levels of Coal Dust Concentration & Mass-Number Correlation at a fully mechanized underground coal mine in Jharia Coal Field. On the basis of my work – I have drawn out an experimental statistically-based linear relationship between “Mass-Number” concentration as measured by the MRE Gravimetric Coal Dust Sampler, MSA Midget Impinger and British Watson Konimeter. I used School of Mines Ventilation & Rock-Mechanics Laboratory as well as Central Mine Research Station (CMRS) laboratory for my work. My research & investigation have been presented in my thesis paper “Surveillance of Airborne Dust in an Indian Coal Mine”.

- Surveillance of Airborne Dust:

- In order to control the production of dust and the pneumoconiosis problem, assessment of respirable dust in mine environment is essential. The concentration of airborne dust varies greatly between different mine working places and a knowledge of these variations, which can only be obtained by measurements, forms essential background to dust prevention. Measurement of dust is physiologically important since it is the only means of determining whether the mine environment is reasonably healthy. Airborne dust survey thus aims at estimating the relative hazard to health of different mining operations and to relate the airborne dust concentrations to prescribed mining standards.

- My Enrollment into Ph.D. level studies in Mining Engineering:

- On completion of my [Abul KM Shamsuddin] post-graduate studies (M. Tech in Mining) in June 1975 – I was enrolled into Ph.D. level study on recommendations from Ministry of Education, Govt. of Bangladesh which was approved by Ministry of Education, Govt. of India. I was proceeding with my Ph.D. level studies – but hearing the death news of Father of the Nation, Bangabandhu Sheikh Mujibur Rahman in August 1975 – I cancelled my Ph.D. programme and came back to Bangladesh to pay my last respect to the Father of the Nation.

- Return to Bangladesh after successful completion of Post-Graduate studies in Mining Engineering:

- After successfully completing Post-Graduate Courses in Mining Engineering, all of us came back to Bangladesh & report to Ministry of Education, Govt. of Bangladesh. We were placed with Bangladesh Mineral Exploration & Development Corporation (BMEDC) in October 1975.

- The Development of Jamalganj Coal Field was not in the mind of BMEDC and we were working in other energy areas.

- In 2005, I retired from Petrobangla as Managing Director of Pashchimanchal Gas Co Ltd (PGCL) and now working as Private Independent Consultant in Oil, Gas, Coal, Mineral & Power Sector. Late Gholam Mostafa retired as Managing Director, Barapukuria Coal Mining Co Ltd (BCMCL) in 2005. Obaidur Rahim & Maung Han Maung migrated to USA in 1976 and worked as Mining Engineer under Federal Govt. of USA.

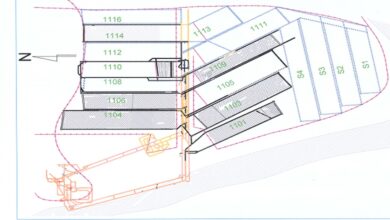

- Background of Jamalganj Coal Deposit:

- Jamalganj Coal Field is located in close vicinity of Jamalganj Town under greater Bogra district was discovered by Geological Survey of Pakistan (GSP) in 1959. The nine bore holes those penetrated the coal seams are spread over an area of a maximum east-west distance of 12.5 km and a maximum north-south distance of 4.8 km. Coal occurs in a typical half-graben basin within the Archaean basement. The coal deposit was about 1054.00 million tons spreading over 8-seams at a depth ranging from 800 meters to 1150 meters. The feasibilities studies were made by M/S Fried Krupp of West Germany Firm in 1966 in a very detail manner and then M/S Powell Duffrin Technical Services of UK re-assessed the report of M/S Fried Krupp in 1969 & recommended to extract coal from Jamalganj deposit.

- The individual coal seam ranges in thickness from less than 2 m to more than 46 m. The average cumulative thickness of coal is taken as 64 m. Coal seams III and VII are the two most important coal layers in terms of thickness, lateral continuity, and reserves. A third seam, i.e. seam IV, also records significant thickness and lateral continuity. Coal seam III records a thickness of 46.82 m. Fried Krupp of West Germany & Powell Duffrin Technical Services of UK found Jamalganj Coal suitable for underground mining as it was technically feasible and economically viable. But the Govt of Pakistan never consider it for mining.

- Petro logical analyses indicate that the upper seams (I-V) have relatively low vitrinite content (19.5-44.2°.0), variable exinitic content (3-22%), and relatively high incrtinite content (24-28%) compared to the lower scams (VI-VII) which leave typically 46.7- 61.4% vitrinite, 5-l0% exinite, mid 22–22.5% incrtinite. Jamalganj coal has been classified as high-volatile bituminous coal. Vitrinite reflectance ranges from 0.66 to 0.84% that suggests that seams I to V are high-volatile bituminous rank and seams VI and VII arc high-volatile bituminous A rank coal.

- After liberation of Bangladesh, Father of the Nation Bangabandhu Sheikh Mujibur Rahman realized that Jamalganj Coal should be exploited for much needed fuel for new born Bangladesh. As a very first step the Govt. decided that Bangladesh need specialized mining engineers for the development of Jamalganj Coal Field. During that period there were about 15-20 graduate mining engineers graduated from the then West Pakistan University of Engineering & Technology [WPUET], (which is now PUET), Lahore working in Bangladesh. There was no Mining Engineering Department at East Pakistan University of Engineering & Technology [EPUET], (which is now BUET), Dhaka. Ministry of Education, Govt. of Bangladesh, selected four mining engineers from different parts of Bangladesh on competitive basis based on their grade of education & working experiences for post-graduate studies in Indian School of Mines, Dhanbad, India.

- Conclusions:

- Jamalganj Coal, being rich in quality & quantity, may be utilized for Power Generation & other Industrial uses. Environmental Issues for deep mining can be handled effectively. Proven technologies are there to curb environmental effects satisfying need of World Climate Concerns.

- Engr. Abul KM Shamsuddin strongly recommends to develop Jamalganj Coal Fields for the benefit of Bangladesh & its people.

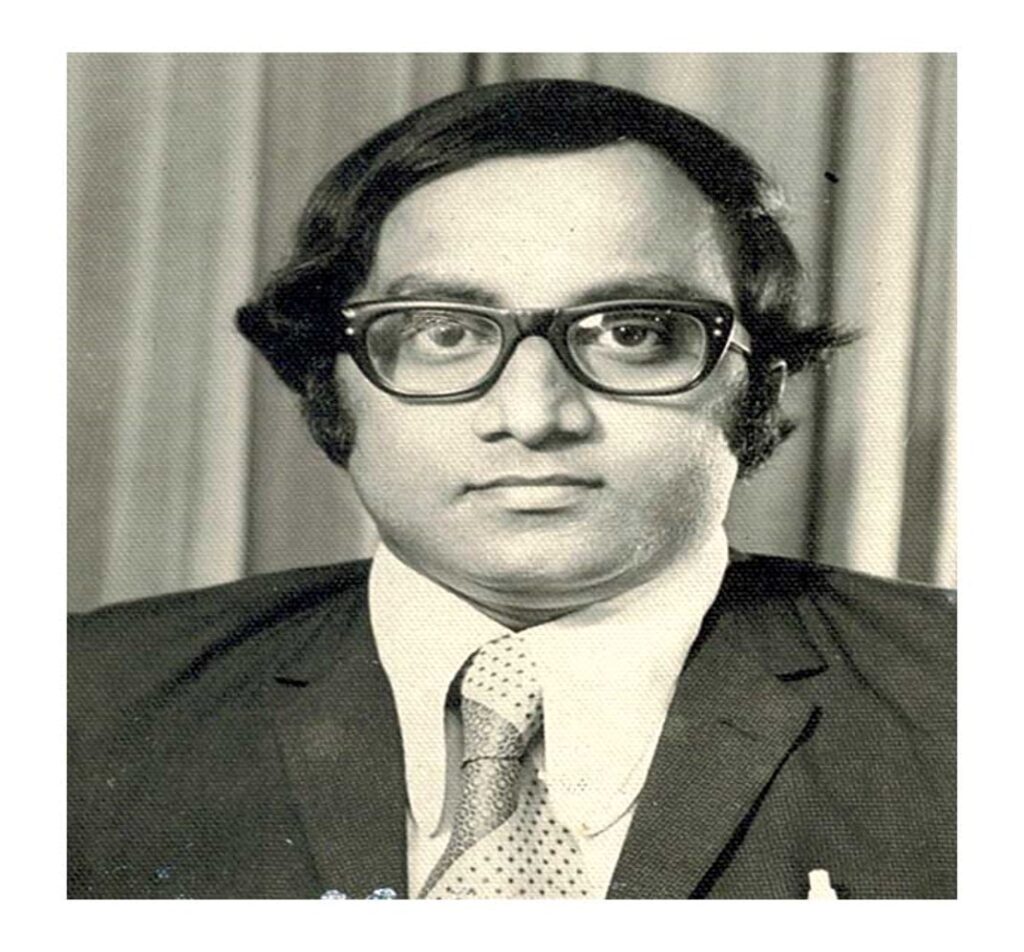

(From Chittagong District) for Post-graduate studies in ISM Dhanbad, India.

Mining Engineering Certificate from Indian School of Mines.

Mining Engineering at Indian School of Mines (ISM), Dhanbad, India.

Gholam Mostafa (center), with 2-ISM colleagues are seen making fun with a chicken roast.